Latest Engineer News And Updates

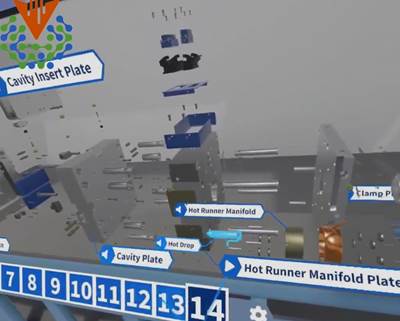

Workflow Automation Transforms Moldmaking Operations

Legacy Precision Molds implements JobTraQ’s no-code workflow automation software to better coordinate complex production tasks across departments, improving efficiency, tracking and decision-making.

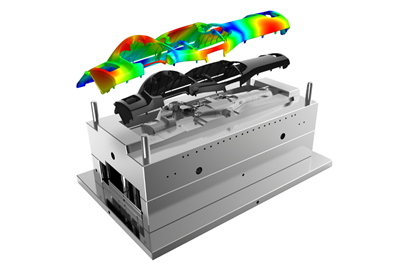

Read MoreBest Practices for Injection Mold Design: The Mold Design Review, Part 4 of 4

Structured mold design reviews are strategic imperatives that resolve design flaws early, minimizing waste and ensuring dimensional accuracy in production.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

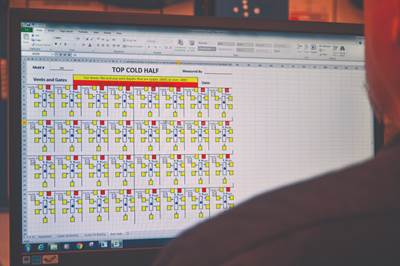

Read MoreDriving Success Through Process Validation and Living Prints

Treat prints as adaptable guides and prioritize rigorous process validation to align tolerances, ensure quality and enable long-term project success.

Read MoreMMT Chats: Ingenuity in Action: Industrial Molds' Engineers Redefine Moldmaking

Industrial Molds’ engineering team showcases ingenuity and precision through complex DFM challenges, delivering optimized tooling, adaptability and customer-driven solutions.

WatchHow Industrial Molds Conquered a Complex Impeller Fan Mold Challenge

Expert engineering team overcomes complex impeller fan mold challenges through innovation, precision and collaborative problem-solving.

Read MoreFeatured Posts

From AI Software to Incorporating Automation into EDM: The Best of November

Our most-viewed November articles included key topics such as AI to enhance efficiency, insights into automating processes, and much more.

Read MoreHow AI Software Can Support Smarter Moldmaking

AI tools help mold shops quote faster, program more accurately and retain critical shopfloor knowledge.

Read MoreHow to Automate Process and Design in Moldmaking

Mold builders can achieve major operational improvements by automating their digital workflows, particularly in CAD/CAM design, programming and process planning.

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreStrategic Mold Venting – Runner Venting

Knowing how to vent runners for cold runner systems can lead to significant process improvements.

Read MoreThe Mold Specification Document, Part 3 of 4

The mold specification document is essential for injection molding success, connecting design requirements with manufacturing processes and quality control standards.

Read More