Workforce Development

Today’s mold manufacturer needs to be watching the next generation, training and teaching them to be the key. Between internship opportunities, in-company academies and certification opportunities, workforce development is an ongoing industry improvement. Learn systems and strategies to further develop a business' workforce, training, education and employee growth.

ESSENTIAL READING

VIEW ALLSmart Tech, Smarter Investments, Skilled Workforce

MMT's Editorial Advisory Board member Gabe English and president of Western Carolina Tool & Mold shares his top MoldMaking Technology articles over the past year and how this content has been valuable to the business.

Read MoreMMT Chat: True Industry/Education Partnership Demands “Consistent Persistence”

High school teachers often ask, "How can I find a company willing to partner with me?" This question may seem straightforward, but establishing a genuine partnership with a local high school to address the skills gap requires ongoing commitment and consistent communication. Electroform, based in Rockford, IL, and Hononegah High School have made that commitment.

WatchHow to Manage Talent to Improve Operational Success

Profitable shops understand that operational and people improvement are inextricably linked. Are you doing what you can to achieve sustainable success?

Read MoreGetting You to Think in Plastic First

For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. The final step is to take the lessons learned from this series and figure out how to impart them to the future moldmaking/molding workforce.

Read MoreHow to Improve Your Current Efficiency Rate

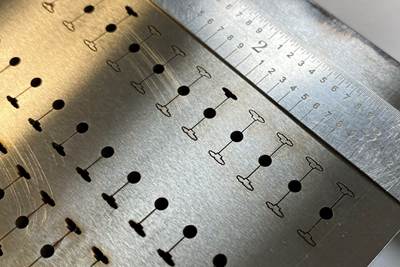

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreLatest Workforce Development News And Updates

From Flow Science to Skilled Hands: A Moldmaking Ecosystem Thrives in Erie

In Erie, PA, a single hub combines advanced technology and services, education and hands-on training to drive innovation and secure the future of moldmaking and plastics.

Read MoreMMT Chat: True Industry/Education Partnership Demands “Consistent Persistence”

High school teachers often ask, "How can I find a company willing to partner with me?" This question may seem straightforward, but establishing a genuine partnership with a local high school to address the skills gap requires ongoing commitment and consistent communication. Electroform, based in Rockford, IL, and Hononegah High School have made that commitment.

WatchBuilding Strong Industry-Education Bonds Through Dedicated Collaboration

High school educators often struggle to connect with businesses willing to partner, but creating a meaningful collaboration to address the skills gap demands ongoing effort and open dialogue. Electroform and Hononegah High School in Rockford, IL, demonstrate this through their steadfast commitment to a true partnership.

WatchMMT Chat: CAMM TechBridge Reinvents Path to Moldmaking Careers

CAMM’s TechBridge initiative leverages virtual reality training and education to inspire students, connect parents and strengthen moldmaking’s future workforce.

WatchBridging the Manufacturing Skills Gap: A Wake-Up Call

Manufacturing urgently needs mentorship programs and structured training before retiring experts create an irreversible skilled worker shortage.

Read MoreHow to Manage Talent to Improve Operational Success

Profitable shops understand that operational and people improvement are inextricably linked. Are you doing what you can to achieve sustainable success?

Read MoreFeatured Posts

Building Skills and Empowering Students

Zero Tolerance LLC partners with Stevenson MADE High School in Sterling Heights, Michigan, to bridge the gap between education and industry by providing hands-on training, mentorship and real-world exposure to precision manufacturing and moldmaking.

Read More30 Under 30: The Next Generation Reshaping Moldmaking

Young professionals are bringing new perspectives, technical skills and strong commitment to the moldmaking industry. MoldMaking Technology recognizes these individuals through our 30 Under 30 program, highlighting emerging talent helping to shape the future of precision manufacturing.

Read MoreCelebrating Tomorrow's Leaders Today

In this special issue, MoldMaking Technology presents our "30 Under 30" feature, highlighting young professionals who are making meaningful contributions to moldmaking before reaching age 30.

Read MoreGetting You to Think in Plastic First

For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. The final step is to take the lessons learned from this series and figure out how to impart them to the future moldmaking/molding workforce.

Read MoreUsing a Simulator to Support Upskilling and Empowering Workers

A virtual machine tool trainer powered by digital twin technology helps bridge the labor gap, starting with school programs.

Read MoreThe Overlooked Solution to Manufacturing's Skills Gap

Experienced manufacturing professionals represent an overlooked talent pool whose tribal knowledge and expertise could solve critical industry problems amid reshoring opportunities.

Read More