In Case You Missed It: Top April Content

Spring has sprung, and knowledge is plentiful this time of year! Catch up on what our readers enjoyed the most this month.

Source: Lethiguel, Dynamic Tool Corp, General Pattern

Spring has sprung, and knowledge is plentiful this time of year! From 3D printing to mold simulation, April covered many topics this month. We know it can be hard to stay up to date on all things moldmaking, so here are the top articles that you may have missed or may want to read again.

10. Defining and Understanding Project Scope

Establishing new product development project scope requires clear goals, resource allocation, champions for technologies, and flexibility for trial and error.

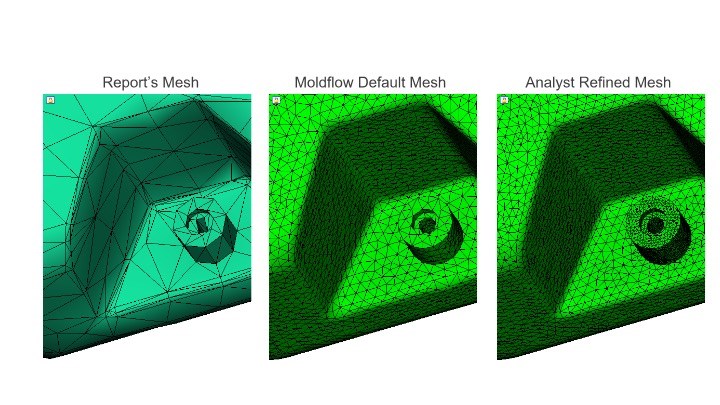

9. How to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Source: American Injection Molding (AIM) Institute

8. How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its business — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

7. Reshaping Tooling Design and Production While Honoring a Rich Legacy

The Plastek Group is redefining its Tooling Divisions with a three-pronged approach: embracing new technologies, fostering collaboration across generations, and driving cultural and operational change under the leadership of three newcomers.

6. MMT Chats: Helping Small Manufacturers Embrace AI

IT Expert Mina Girges shares simple ways to implement AI by starting small, fostering innovation, integrating securely and scaling strategically to enhance efficiency.

5. New DOD Marketplace Caught My Eye

DOD platform opens doors for advanced manufacturers — timely given recent shop talks and past coverage.

4. 5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.

3. Warpage Waylaid Via Simulation

Designed to form a component that would hold headlights in place, the mold was intended to produce a front-end automobile bracket. Instead of parts however, the tool’s real output was problems.

Source: TST / Tooling Software Technology LLC

2. How to Expand the Use of Aluminum Injection Molds

Six factors to consider to broaden the application of aluminum molds.

1. Deep-Cavity Cooling Made Easy

G.A. Roeders uses an advanced cooling system employing gundrilling to deliver high-pressure water to quickly and evenly cool areas deep within a mold cavity.

Related Content

-

What Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.