Data Management Software and Enterprise Resource Planning

ERP stands for “Enterprise Resource Planning.” Some of the functions associated with ERP and related management software include: Costing or estimating the time and cost of production, scheduling a job for production, and in-process job tracking, or logging each step in a part’s progress through the shop, so a part’s current status can be immediately known. ERP systems also provide a historical view of resources required on prior jobs which can be very helpful in planning new work.

ESSENTIAL READING

VIEW ALLHow to Automate Process and Design in Moldmaking

Mold builders can achieve major operational improvements by automating their digital workflows, particularly in CAD/CAM design, programming and process planning.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

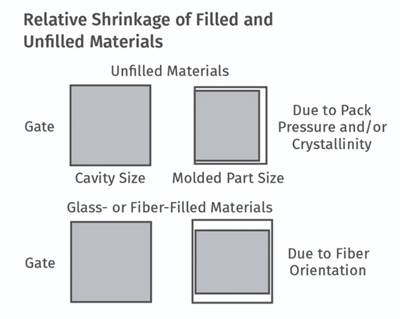

WatchBest Practices for Hitting Critical Numbers: Communication and the Shrinkage Factor

Start with an upfront review, discussion and collaboration with the customer and then consider the shrinkage factor.

Read MoreWhat Is Design for Manufacturing? Part 1 of 4

A DFM review ensures part design meets injection molding standards, enhancing cycle time, yield and aesthetics. Here are key considerations for the review.

Read MoreSimplifying Cooling Design With Advanced Automation

CAD/CAM software with automated mold design features streamlines waterline, baffle and conformal cooling design, making it easier to act on insights from flow analysis.

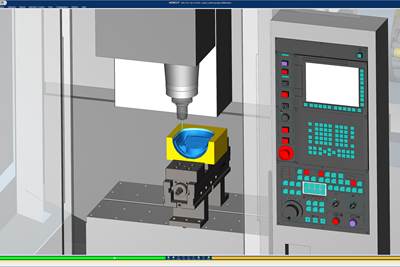

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreLatest Data Management Software News And Updates

From AI Software to Incorporating Automation into EDM: The Best of November

Our most-viewed November articles included key topics such as AI to enhance efficiency, insights into automating processes, and much more.

Read MoreHow AI Software Can Support Smarter Moldmaking

AI tools help mold shops quote faster, program more accurately and retain critical shopfloor knowledge.

Read MoreHow to Automate Process and Design in Moldmaking

Mold builders can achieve major operational improvements by automating their digital workflows, particularly in CAD/CAM design, programming and process planning.

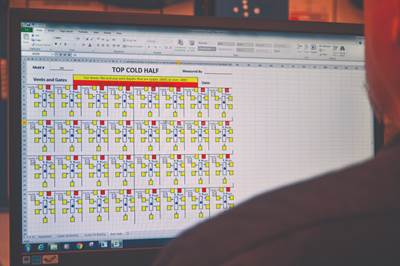

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThe Mold Specification Document, Part 3 of 4

The mold specification document is essential for injection molding success, connecting design requirements with manufacturing processes and quality control standards.

Read MoreWhy Is Flow Simulation an Essential Design Tool? Part 2 of 4

Flow simulation is crucial for understanding how molten plastic behaves within the mold cavity. Accurate simulations inform decisions about gating, runner layouts and cooling designs.

Read MoreFeatured Posts

Machine Sizing and Specification for Optimal Mold Performance, Part 1

Guidelines to ensure proper mold fit and maximum efficiency in injection molding machines.

Read MoreLevel Up Your Moldmaking With AI

AI-powered technologies, including feature detection, improve moldmaking efficiency and accuracy, enabling experts to focus on innovation.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

WatchBest Practices for Hitting Critical Numbers: Communication and the Shrinkage Factor

Start with an upfront review, discussion and collaboration with the customer and then consider the shrinkage factor.

Read MoreSensors, Sustainability and Skilled Labor

Q&A with Bob VanCoillie, MoldMaking Technology EAB member and senior manager of Kenvue’s mold management center of excellence.

Read MoreReal-Time Mold Monitoring Boosts Molding Efficiency and Cost Savings

FloControl software integrates with existing mold design tools, offering real-time tracking and optimization from design to production, enhancing efficiency and reducing costs for ProPlastics.

Read More