Westfall Technik Promotes Integrated Hot Runner, Tooling Technology at Amerimold 2021

Proprietary technology from Westfall Technik produces parts ranging from 0.001 g to 400 lb and are designed for longevity and reliability.

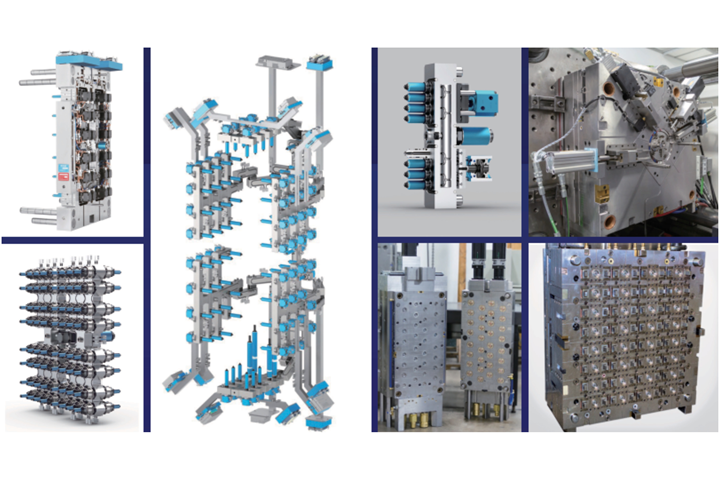

Photo Credit: Westfall Technik

Westfall Technik has developed proprietary hot runner technology to produce parts ranging from 0.001 g to 400 lb. The easy-to-maintain hot runners are designed for longevity and reliability.

At Amerimold 2021, Westfall says it will showcase compact internal valve gate nozzles; O-ring free black box actuators; removable cartridge manifolds; moving slide manifolds; angled valve gate technology; easy-to-operate star gate nozzles and multi-tip valve gate nozzles; and ISOKOR hot runner technology for micromolding.

Westfall will also promote its advanced high-precision (± 0.001”) micro molding and high-precision, high-cavitation tooling solutions with integrated hot runners. With its stacked integrated model and advanced engineering team, Westfall says it is able to help moldmakers and custom molders improve quality and reduce costs.

Exhibitor: Westfall Technik

Booth 539 (P)

Related Content

-

Understanding Manifold Thermal Expansion

Molders, mold builders and repair technicians must fully understand thermal expansion to ensure they don’t damage critical seals during manifold repairs or routine cleanings.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Troubleshoot "Actual" Hot Runner Controller Temperature

A first-person account of how one technology supplier did not give up until it solved the mystery of a recent part defect.