VIDEO: Optimizing Mold Measurement with CMMs

Portable, shop-ready CMMs enhance precision, speed, and efficiency.

Tony Almeida Regional Sales Manager at Mitutoyo America Corporation shares how mold builders can achieve precise, efficient mold measurement using advancements in surface roughness testers and compact CMMs.

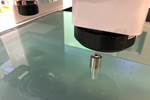

Portable surface roughness testers streamline the measurement process, allowing direct application on large or heavy molds. With single-button operation and vivid color displays, these devices ensure user-friendly experiences.

Also, compact CMMs like MiSTAR offer shopfloor readiness and cantilever designs that support the side loading of large workpieces. Equipped with touch panels and software integration options, they are ideal for operations as inline automation gains momentum.

On the software side, MiCAT Planner simplifies the programming process, converting complex CAD geometries into actionable measurement plans. This eliminates steep learning curves, helping moldmakers maximize efficiency.

Looking ahead, technological advancements in CMMs and software automation will significantly shape the moldmaking industry in the next five years, driving precision and productivity further.

Click here to check out more videos.

Related Content

-

How to Assess and Control Surface Texture Quality

Surface texture measurement offers better methods for describing plastic surfaces.

-

Breaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.