Hot runner controller and molding machine integration is a big topic right now and tooling managers are taking notice because a lot of companies are trying to use the molding machine hot runner controls to run tools that are too big for the number of zones available on the molding machine. Using some control from the molding machine and the rest from a stand-alone controller can be disastrous (leaking tools, steel expansion wear, burnt and spitting material, unnecessary peak amp draws, uncontained scrap, operator confusion and inefficiency).

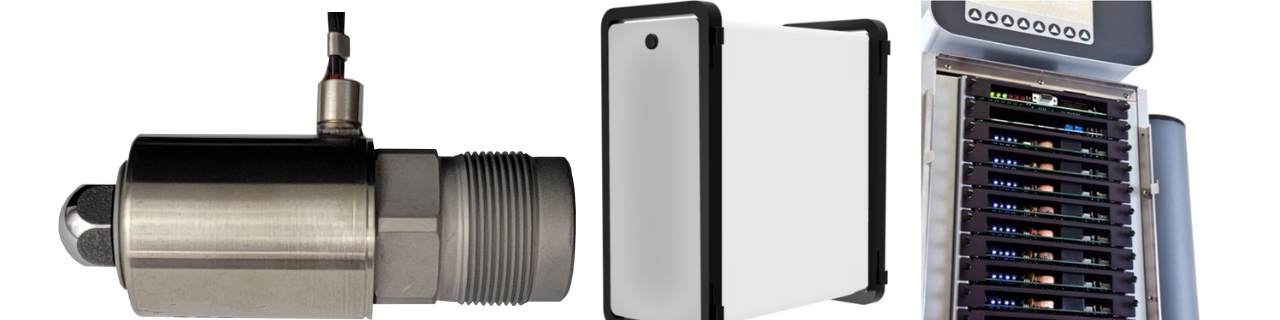

Here Chad Root Managing Partner for Fast Heat by Spark Industries breaks down a few molding machine integration concepts that protect hot runner systems, the molding machine, reduce scrap and help keep a log of events.

For more video content from MMT, visit

https://www.moldmakingtechnology.com/videos

Related Content

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

-

What Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.