Too Old for the Form, Too Good to Ignore

Our “30 and Under” Honors Program celebrates young professionals who are shaping the future of manufacturing. Occasionally, we encounter a candidate whose drive, innovation and leadership deserve recognition — regardless of their age. One such individual is Andrea Gruber.

Andrea Gruber, a standout PhD candidate in Plastics Engineering at UMass Lowell, excels in injection molding, mold design and polymer process engineering, demonstrating exceptional technical depth, leadership and mentorship. Source (All images) | Andrea Gruber

Andrea Gruber is a PhD candidate at the University of Massachusetts Lowell. While she may not fit our original age criteria, her exceptional technical expertise, leadership and mentorship in injection molding, mold design and polymer process engineering clearly illustrate the future of manufacturing.

I will begin by sharing the nomination form submitted by Davide Masato, an Associate Professor at UMass Lowell and a former member of the MMT Editorial Advisory Board, which inspired me to learn more. After that, we will explore her journey in greater detail, including the lessons she has learned and the innovative ideas she is bringing to the fields of plastics and moldmaking.

Andrea is an exceptional PhD candidate in Plastics Engineering at UMass Lowell who has demonstrated outstanding technical depth, leadership and mentorship in the areas of injection molding, mold design and polymer process engineering.

“I try to encourage students to see moldmaking not just as manufacturing but as a systems-level design challenge.”

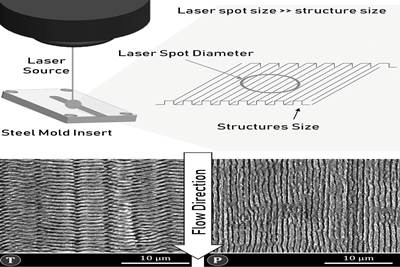

Her doctoral research, titled “Evaluation of Thermal Interface Phenomena in Precision Injection Molding,” addresses a critical challenge in tool design and process control: heat transfer at mold–polymer interfaces. Supported by industry partners interested in advanced mold design, cooling technologies and thermal contact resistance (TCR) modeling, Andrea’s work integrates experimental methods, statistical analysis and simulation — including Autodesk Moldflow — to generate practical insights that directly benefit moldmakers and processors focused on performance and efficiency.

Andrea has developed deep hands-on expertise across the full mold development process: part and mold design, simulation, CAM, machining, polishing, assembly and molding. In the 2024–2025 academic year, she served as a teaching assistant for the department’s mold engineering course — the ABET-accredited culminating design experience — and played a central role in helping student teams successfully design, build and test six functional injection molds. She also supported student teams working on end-of-arm tooling (EOAT) projects, reinforcing her comprehensive knowledge of tooling systems and automation.

As a testament to her impact, Andrea was named Teaching Assistant of the Year in 2024. Yet she is most proud of the students she has mentored — many of whom are now applying mold engineering principles in real-world industrial settings. Without her guidance, these complex student projects would not have reached the high level of completeness, functionality and professionalism expected in this advanced course.

Beyond her teaching and research, Andrea has contributed to technical conferences such as ANTEC and the Autodesk Moldflow Summit, where she has engaged with the broader engineering and simulation community. She consistently brings clarity, rigor and collaboration to her work — earning the trust of both faculty and peers.

Andrea is a thoughtful and capable engineer whose work reflects both technical excellence and a strong understanding of practical manufacturing needs. Her ability to connect simulation tools with hands-on mold building and process development sets her apart. As she transitions into her industry career, Andrea brings with her a well-rounded skill set, proven leadership in collaborative environments and a deep commitment to engineering quality — making her highly deserving of the MMT recognition.

Q&A

1. Your PhD research explores thermal interface phenomena in precision injection molding — a highly technical and niche topic. What initially drew you to this specific area of mold design and process control?

What drew me in was realizing how little we truly understand about what happens at the mold–polymer interface during injection molding. Everyone talks about optimizing cycle time or improving part quality with high-end technologies, but we often overlook the fundamental physics that drives the process. In particular, how the heat transfer at that interface can dramatically impact both part replication and cooling efficiency. This led me to study thermal contact resistance because I saw a real gap in both experimental methods and how it’s treated in simulations. It’s a niche topic, but it has a significant impact on performance and energy consumption, especially as we transition to more precise, high-temperature polymers and micro-featured molds.

Named 2024 Teaching Assistant of the Year, Andrea is most proud of mentoring students now applying mold engineering skills in real-world manufacturing environments.

2. You’ve developed hands-on skills in every stage of the mold development process — from CAD/CAM and machining to polishing and molding. Which part of this process do you find most rewarding or challenging, and why?

For me, the most rewarding part is the transition from design to physical mold —when you finally go from a CAD model to something you can hold, assemble, and run in the machine. There’s a unique satisfaction in seeing a part mold successfully that you helped design from scratch. That said, polishing and surface prep are among the most challenging steps. Small details can make a big difference in part ejection, venting and especially heat transfer at the interface. I’ve learned not to underestimate the effect of surface finish on thermal behavior — it’s something that I’m studying deeply in my research.

“Helping students forced me to really think about why we do things a certain way, not just how.”

3. During your time as a teaching assistant, you mentored student teams through complex mold engineering projects. How has that teaching experience shaped your own engineering perspective — and what impact do you hope to have on the next generation of mold designers?

Helping students forced me to really think about why we do things a certain way, not just how. Helping with the class helped me internalize principles more deeply, such as logic gate placement, venting and cooling strategy. It also gave me perspective on the value of hands-on experience for young engineers. I try to encourage students to see moldmaking not just as manufacturing but as a systems-level design challenge. If I can help shape designers who are technically solid and curious about the “why” behind the process, I’ll feel I left something meaningful behind.

Helping students deepened Andrea’s understanding of mold design principles and highlighted the importance of hands-on experience for developing future mold engineers.

4. You’ve engaged with the industry through ANTEC, the Autodesk Moldflow Summit and research partnerships. What feedback or insights from industry partners have most influenced your work — and how do you see that academic-industry collaboration evolving in the future?

Industry feedback has been key in helping me focus on what’s implementable. For example, discussions with partners at Autodesk Moldflow and companies like Corning and Dassault Systèmes made me realize that while complex simulations are helpful, there is a real need for experimental data to validate them, especially when it comes to thermal interfaces. It’s one thing to simulate a perfect contact; it’s another to understand what’s happening with a real, textured steel surface. I see academic-industry collaboration evolving into more integrated, problem-driven partnerships, particularly in areas such as sustainability, processing and advanced materials. I think we’ll see more demand for people who can bridge lab research with shop floor realities.

5. As you prepare to transition from academia into the manufacturing workforce, what type of role or company culture are you seeking — and how do you hope to make an immediate impact in the moldmaking or plastics engineering space?

I’m looking for a role where I can stay close to the process — ideally in a company that values both technical depth and experimentation. I enjoy working with cross-functional teams, especially when there’s room to question assumptions and improve designs based on real-world testing. Whether it's in process development, mold design or R&D, I aim to leverage both my research background and hands-on experience to enhance molding processes, making them more efficient and better understood. In terms of culture, I value transparency, curiosity and people who are passionate about making things better, not just faster.

Related Content

Best Practices for Hitting Critical Numbers: Communication and the Shrinkage Factor

Start with an upfront review, discussion and collaboration with the customer and then consider the shrinkage factor.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreConfronting the Mold Design Talent Drought

Recently, I reposted on LinkedIn the results of an informal survey we conducted, which revealed a shortage of skilled mold designers. It quickly gained a lot of traction. Given the response, I thought I'd summarize the feedback and keep the conversation going.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreRead Next

A Look at Three Mold Surface Effects

Identifying and testing innovative injection mold surface properties became an unexpected theme of recent virtual content—ultrafast laser texturing, coatings and plasma.

Read MoreAn Academic Analysis of Moldmaking’s Workforce Challenges

Understanding and facing the moldmaking industry’s obstacles to growth requires a strategy focused on increased profitability.

Read MoreMMT Chats: Virtual R&D and Teaching Plastic Injection Mold Design

New Editorial Advisory Board member Davide Masato, an Assistant Professor at the University of Massachusetts Lowell, joined me for a 20-minute video chat about the importance of plastics engineering, and how COVID-19 changed the faculty's approach to teaching mold engineering and plastics research.

Read More