Tips

How AI Software Can Support Smarter Moldmaking

AI tools help mold shops quote faster, program more accurately and retain critical shopfloor knowledge.

Read MoreHow to Quickly Check Cooling Channels

Smart hole inspection validates possible leakages and strangulations in the cooling channels by doing tightness and flow rate tests.

Read MoreMaterial Choice Considerations for Mold Venting

A comparison of high-tonnage pressed steel—such as H13, 420 stainless, P20 and pressed porous venting mold steel—and 3D printed tooling.

Read MoreWhat Machinists Should Look for in Toolholder Technology

Evaluate toolholders for reach, stability, quality and speed capability to maximize machining precision and productivity.

Read MoreCan Robots Help Make Molds?

Automation can benefit mold production, from optimized efficiency to enhanced product quality and consistency.

Read MoreThe Benefits of Investing in Sinker EDM Training

Beyond technology upgrades, mold builders can boost cost savings, productivity and quality by prioritizing operator training in two key areas.

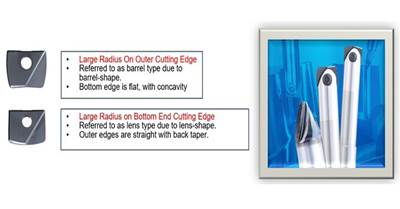

Read MoreWhy Mold Builders Should Consider Barrel Cutters and Lens Tools If They Haven’t Before

Reduce machining cycle times and improve surface finishes of cavity and core work with barrel cutters and lens tools.

Read MoreHow to Expand the Use of Aluminum Injection Molds

Six factors to consider to broaden the application of aluminum molds.

Read MoreHow To Break Free From CMM Dependency

Moving from CMM to in-process verification requires investment in equipment, processes and people to maintain quality standards.

WatchHow to Reduce or Eliminate Surface Defects

Localized mold temperature control with targeted heat pulses improves part surface quality and cavity filling.

Read More