Technological advancements are only one axis of improvement in electrical discharge machining (EDM). Manufacturers may be able to achieve greater performance in terms of cost savings, productivity and quality by investing in training rather than focusing only on equipment upgrades. The key training areas for any EDM operator should include two primary topics.

- The operator should gain a complete understanding of the machine tools they are operating. This training is typically available through the OEM and should include basic/advanced operation, maintenance, programming and navigation of the machine technology.

- EDM operator training should include the effects that consumable materials have on the process. The performance interactions between electrodes and workpiece materials are a key piece of the EDM process. Reviewing the relationship between electrode and workpiece materials extensively — including the way that each consumable impacts the overall process — is key. While this information is critical, it’s also hard to access and formalized training is the best course of action.

Understanding the Importance of Sinker EDM Training

Most trainees are either engineers who have been given responsibility for the EDM process or operators who are accomplished machinists but are new to the EDM process. EDM training is beneficial if it unites machine tool operation, concepts of the thermoelectric model and consumable variables.

Although operators can refer to the manual for their machine, many variables are outside the scope of the machine tool manual. As experienced EDM operators leave the industry, there’s also no way to learn on the job under the guidance of a more experienced individual.

Training based on graphite materials science helps make up for the lack of skilled mentorship by delving into the properties and characteristics of EDM electrode materials and their impact on the EDM process. The goal is to educate students on the importance of electrode material selection, enabling them to optimize their processes and effectively evaluate their results.

Technical challenges for EDM operators only continue to rise based on decreasing feature sizes and increasing complexity. New equipment can offset some of these difficulties – only increased knowledge can take care of the rest.

Coping With Increasing Customer Requirements

EDM training benefits engineers new to EDM and skilled machinists by combining machine operation, thermoelectric concepts and consumable variables for a comprehensive understanding.

Many EDM operators report that their customers are requesting more complex parts. This usually means smaller overall parts with an increased number of small features, as well as a finer surface finish due to the challenges of polishing.

Producing parts to these tight specifications using sinker EDM requires technical knowledge. Here are three performance factors that can be greatly improved with thorough knowledge of the process:

- Surface Finish

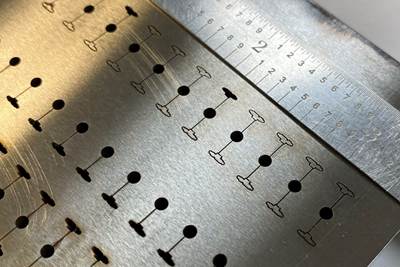

Fine surface finish is obtained with the proper electrode material, good flushing conditions and the appropriate power supply settings. The final surface of a finished workpiece will mirror that of the EDM electrode. This means that selecting the correct electrode material has a huge effect on the final product. It’s important to know which graphite grades have the correct particle size, strength and structure to create the desired surface characteristics.

- Wear Resistance

The contours of the final cut are determined by an electrode’s ability to resist the erosion of its corners and edges. Electrodes that wear out at corners and edges must be replaced more frequently. Minimizing corner wear requires choosing an electrode material that combines a uniform microstructure with high-temperature resistance.

- Machinability

It is common knowledge that most graphite is easy to machine. However, simply being easy to machine doesn’t necessarily make a material the best choice for an electrode. It must also be strong enough to resist damage from both handling and the EDM process. Strength, combined with small particle size, also helps achieve minimal radii and tight tolerances. Material hardness is also a factor in graphite machining, as harder electrode materials will be more prone to chipping during the machining process.

Understanding these factors will help operators adjust to a changing customer landscape and applying this knowledge will generate immediate improvements. Let’s look at a real-life case study where new insights helped a manufacturer solve a frustrating problem.

Solving Increased Electrode Wear and Slow Burn Times

A manufacturer faced productivity losses in fabricating carbide materials. Increased electrode wear forced the company to spend more on electrode material and led to higher fabrication costs.

To fix this, the company sent an employee for EDM training. The training included detailed information about the relationship between the EDM electrode material and the workpiece. An important topic covered how the physical properties of the workpiece determine the parameters to choose for best performance.

The student learned that choosing an electrode material based on properties and performance — rather than low cost — would enable them to increase productivity, decrease electrode wear and significantly reduce their overall material expenses while increasing their profit margins.

Materials Training Leads to EDM Success

Training that explicitly highlights the relationship between the workpiece material and the electrode is information not detailed in the machine tool manual or passed down from experienced EDM operators.

This makes comprehensive formalized training — like Entegris Poco Material’s free program that covers essential topics in both basic and advanced EDM training — vital to current and future operators. The only requirement is a modest investment in time and travel expenses to participate. Several leading manufacturers have incorporated this training course as a mandatory part of the onboarding process for their EDM operators. Also, for those unable to attend in-person sessions, there is a virtual training platform for the basic course, enabling participants to engage at their own pace and convenience.

Technical challenges for EDM operators only continue to rise based on decreasing feature sizes and increasing complexity. New equipment can offset some of these difficulties — only increased knowledge can take care of the rest.

Related Content

MMT Chats: AI on the Shop Floor Now

In this MMT Chat, I had the pleasure of sitting down with Mike Murakami, wire and sinker EDM lead hand at StackTeck Systems, to explore how artificial intelligence (AI) is quietly—but powerfully—transforming moldmaking.

Read MoreCAM for Sinker EDM Benefits Mold Cavity Work

Standalone programming module for sinker EDM optimizes cavity burn parameters, ensuring the first parts are correct and the process efficient.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreExtensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Read MoreRead Next

An Added Layer of EDM Knowledge

Understanding electrode material selection and the relationship among the electrode, workpiece material and machine parameters can improve EDM efficiency.

Read MoreHow EDM Training Can Boost Productivity

Even the shortest of training sessions provide the opportunity to recover any costs incurred in a very short time.

Read MoreImprove Your Current Efficiency Rate

Ernie Green Industries gives an account on how it took on more EDM-intensive work without investing in machines or staff.

Read More