Student Executives Manage Business, Academia in High School Vocational Program

Bend Manufacturing, a business led by high school seniors that operates out of The Portage School of Leaders in South Bend, Indiana, is witnessing its real-time return on investment: its students.

A glimpse of Bend Manufacturing’s facility, located inside of The Portage School of Leaders. Three Bend Manufacturing employees, who are also high school students, can be seen deliberating the business’ daily workflow in their classroom.

Source: Additive Manufacturing Media (all images)

Bend Manufacturing, a student-led business based in South Bend, Indiana, operates entirely out of the maker space at The Portage School of Leaders. Its C-suite? Completely comprised of high school seniors — some already knee-deep in work with local manufacturers, some prepared to enter the industry immediately following graduation.

Bend Manufacturing was established alongside The Portage School of Leaders, a leadership-focused high school that opened its doors in 2024. The school received a 4.4 million-dollar-grant, in conjunction with the local Boys and Girls Club, to both renovate and build out the Bend Manufacturing facility (formerly a synagogue) and travel in pursuit of equipment and guidance for the business-centered program. Led by teachers David Ebersol and Justin Baney, the business operates as an optional elective class, offering dual high school- and college-level class credits to students — putting students well on their way to earning an associate’s degree upon high school graduation. The industrial learning facility, called the Future Lab, includes a standard classroom, a fully operational machine shop, wood shop and separate maker space, all located on school grounds. It features everything from manual mills and lathes to a selection of 3D printers, offering a well-rounded skill set to students.

Some of the facility’s notable machinery includes three Haas three-axis CNC milling machines, a Formlabs Fuse 1+ SLS powder 3D printer, a Stratasys J55 3D printer, a six-axis cobot arm, several manual mills and lathes, a Markforged FX-10 and a Markforged Metal X System for metal 3D printing, the latter of which was purchased during a school visit to IMTS 2024. Bend’s 3D printers and AM equipment are typically used for rapid prototyping.

Ebersol featured alongside the facility’s six Haas high-speed milling machines, which are fully available to high school students at Bend Manufacturing.

The Portage School of Leaders is part of the Career Academy Network of Public Schools, serving K-12 students in South Bend. Technical skills are nurtured periodically from kindergarten through eighth grade, preparing prospective students to enter the high school program. Each of the school system’s buildings has its own maker space, run by an educator with a role akin to a librarian. K-5 students begin by learning slicing programs from Prusa and Bambu, continuing to learn about layer heights and TinkerCAD when they reach fourth grade. Students then begin creating flat planes as in-class projects, like key chains and various art pieces. From sixth until eighth grade, the students’ focus shifts to learning about vertical alignments using CAD and AM. Sixth graders’ first goal is to design a coin in CAD, then 3D print the model. These projects enable students to understand workflow from as early as kindergarten and beyond. When entering the high school level, students begin to learn CAM and programs like Autodesk Fusion 360 for 2D cutting and have full access to the Future Lab at The Portage School of Leaders.

Ebersol, featured in front of a manual mill with a NIMS certification test. Students have the option to pursue NIMS certification, among others, throughout their education.

Ebersol and Baney’s primary goal is to provide a strong foundation for students to enter the industry with. This includes encouraging students to obtain important certifications, like NIMS, Adobe certification using programs like Adobe Illustrator, QuickBooks and various others. Thus far, 55% of students have assumed manufacturing careers immediately following high school graduation, while 35% have continued onto higher education. The remaining 10% have entered the military.

“Education is freedom,” Ebersol says. “The more certifications I can get them, the more tools they have in their toolbox, and the more successful they can be.”

VARIOUS equipment at Bend manufacturing

Balancing Labor and Education

However, the education model is 10% teachers’ labor and 90% of what students bring to the table. This is especially true for the students who opt to spend part of their time at school working within the Bend Manufacturing business embedded at the Future Lab. Ebersol and Baney make it clear to students that they are present to oversee all operations, but it is the responsibility of the students to seek out projects and direct them, communicate with clients, and manage all finances.

Participating in the Bend Manufacturing program is optional for the high school students, but there are perks to doing so — including additional training on the facility’s equipment, hands-on experience with running a business and the chance to earn money for their labor. Students are paid by commission, with their wages managed by the chief financial officer (CFO), typically a high school senior. The CFO manages, quotes, and ultimately prices out each project via spreadsheet, assessing factors like set times, run times and material costs. The four-tier pay structure operates on an evaluation of individual hours, with 51% of pay allocated to students after expenses. While all students in the program are required to fulfill seven hours of attendance per week, some students assume individual internships or choose to work longer hours during their free time, therefore increasing their pay.

Miscellaneous 3D printed art projects, some commissioned by teachers to be displayed in classrooms, created by students at The Portage School of Leaders in the Future Lab. Teachers have previously commissioned various products from Bend Manufacturing, including gardener’s boxes and metal signs for their respective classrooms.

Inspired by the Cardinal Manufacturing educational model, which launched at Eleva-Strum Central High School (Strum, Wisconsin) in 2007 as one of the first American student-led manufacturing businesses and dual-credit courses of its kind, Bend Manufacturing aims to be a community-centered business. Alongside aiding teachers and administrators with various projects, like machining metal signs for classrooms and school events, Bend also offers its services to local businesses and establishments, like the South Bend Civic Theatre, where students freely chose to spend their Thanksgiving break creating props for the theatre’s November 2024 production. As customers in the community began to hear of Bend by word of mouth, news of its student-driven contract services have spread beyond the local level, granting external customers the opportunity to nurture the talents of young people entering the industry and leverage what have often been lower costs of labor. While Ebersol and Baney still source projects for the business, it is largely the responsibility of students to contact potential customers.

Outside of its community, Bend has completed contract work for large companies and universities, like the University of Notre Dame, as well as various defense-centered initiatives. One of its most notable contract projects was with NASA, where the students 3D printed airfoils for wind tunnel models. The airfoils had previously been made from aluminum, but Bend found 3D printing said airfoils from composite-reinforced plastic filament on its Markforged FX-10 to be more time- and cost-effective. Bend was able to cut NASA’s lead time down to 11%, while also cutting costs by 30%. These projects are encouraged from the introductory level and onward, with even the 2024 class of incoming freshmen assuming customer commissions at the beginning of the school year.

An airfoil commissioned by NASA, made of composite-reinforced plastic filament, which Bend Manufacturing 3D printed using its in-house Markforged 3D printer.

Student Leaders Pave the Way

Ebersol and Baney claim the students are Bend’s true return on investment. They hope to instill a spirit of dedication within their classes, which student leaders can then pass along to their peers. For example, Bend’s current C-suite, a leadership board of student executives, is encouraging its fellow students to practice proper social etiquette daily, in what they call “Walk In, Stand-Up Meetings.” These meetings include ensuring that students are standing to greet one another, shaking one another’s hands upon meeting each day, making engaged eye contact, partaking in meaningful conversations and even practicing table etiquette for future professional events.

Bend’s “Gameboard” spreadsheet is another of its joint social and professional efforts. Housed in Google Sheets, the Gameboard serves the purpose of an ERP system for Bend Manufacturing and is where the student employees record the progress of jobs in work. Students review the Gameboard with Ebersol and Baney each morning, discussing project statuses, offering new ideas and allotting responsibilities to individual students in a classroom round table. Students are expected to lead the daily conversation, offering personal insight and support to one another while learning to manage a seven-day workflow.

Baney overseeing a student-led overview of the Gameboard, which details Bend Manufacturing’s operations and acts as its ERP system.

I had the opportunity to speak with Bend Manufacturing’s student-led C-suite, consisting of COO Garrett R., CMO Isaac N.B. and CFO Gavin T., all high school seniors with plans to pursue manufacturing careers or higher education degrees in engineering following graduation. All three students underwent an interview process, along with an assessment of their respective skill sets, for their executive roles. Their feedback was overwhelmingly positive, collectively stating that their roles have granted them opportunities to not only hone their skills, but utilize them in support of their passions and peers. And, as CMO Isaac N.B. says, “it’s fun. It’s a chance to be creative.”

The C-suite, however, is teetering upon graduation, and therefore learning how to manage the quick turnover of their own jobs. When scouting Bend’s next executives, the current C-suite is ultimately valuing strong communicative and collaborative skills in their fellow students.

“Communication is only as good as how you communicate,” Garrett R. says. “It’s better to miscommunicate than not to communicate at all.”

Editor Jessica Pompili discussing Bend Manufacturing’s operations with its student-led C-suite. Pictured (left to right) are CMO Isaac N.B., COO Garrett R. and CFO Gavin T.

They encourage their successors to be open-minded, talkative and helpful to their fellow students, while also accentuating the importance of asking for help themselves. The executive students each credited the program with instilling within them a sense of determination and pride in their own futures, stating that Bend, as well as Ebersol and Barney, had given them what was most necessary to their personal and career growth — a safe space to fail.

“Don’t be afraid to fail,” Garrett R. says. “We’ll try it, and if it doesn’t work, we learn from it. Then, we try again.”

Related Content

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreEden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreRead Next

Kent State, Iten Industries Partner for 3D Printing Education

Iten Industries’ goal is to drive internship and engineering experience in the area with students getting hands-on experience with the company’s additive manufacturing printers.

Read MoreCarnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

Read MoreStudents Use Micro Metal 3D Printing for ISS Microgravity Experiment

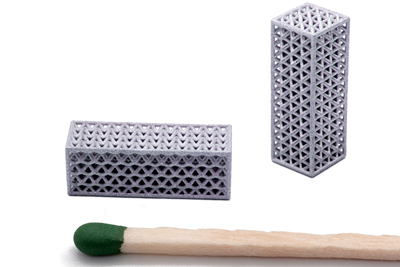

Qualified3D printed lattice parts for the students using microstereolithography (micro SLA), which seemed to be the only process able to produce the parts with sufficient accuracy.

Read More