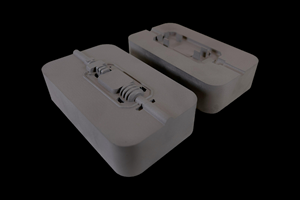

The Fast-Track Tooling methodology leverages readily available assets, including smaller off-the-shelf mold components and bases, with various functional elements and hot runners for one-, two- or four-cavity designs. Source (all images) | MGS

Who is MGS Mfg Group?

Ben Suxstorf, GM, U.S. Tooling: MGS is headquartered in Germantown, Wisconsin. We are a leading health care plastics contract development and manufacturing organization (CDMO) providing end-to-end solutions to health care innovators. Serving top pharmaceutical, diagnostic and medtech companies, we combine robust, vertically integrated global capabilities —from upfront design to full assembly — with the customer focus and agility of a trusted partner. With 12 global locations, MGS helps bring vital innovations to life through seamless collaboration and expertise.

Specializing in ultrahigh cavitation tooling, sophisticated multishot molding and automated assembly and packaging systems, we deliver more than high-volume manufacturing. Our plastics engineering and manufacturing services support every stage of the process, including product design and development, tooling, automation and production. At every step, MGS focuses on mitigating risk, maximizing resources and accelerating speed-to-market for its customers.

What is MGS' Fast-Track Tooling Program?

Suxstorf: This tooling strategy enables companies to design and test medical device components using standardized, modular tooling, enabling early validation of design and manufacturing processes without significant investment in production molds. It accelerates time-to-market, reduces risks and is widely used by pharmaceutical, diagnostic and medtech companies.

What is new with the program?

Suxstorf: MGS has introduced its innovative Fast-Track Tooling Program to the North American market. Originally developed by European-based Formteknik, now part of MGS, this methodology leverages readily available assets, including smaller off-the-shelf mold components and bases, with various functional elements and hot runners for one-, two- or four-cavity designs.

MGS engineers leverage decades of tooling expertise, taking standardized components beyond expectations, and integrating specialized tooling such as servo, two-stage, unscrewing, split molds, stripper and more. This enables them to develop complex, high-performance tooling that today’s sophisticated health care innovators need while guaranteeing the fastest time-to-market.

One of the most critical factors is gating. With our Fast-Track Tooling Program, we're able to use the same valve gate style, location and diameter that will be used in the production mold. This means that the parts we produce during development are much closer to what we'll see in the final product, helping us move forward faster.

It also offers speed and agility to develop and iterate tooling designs at a fraction of the cost of full-production tooling. This critical step helps identify any potential issues or defects early in the development process and gain valuable insights from early supplier involvement (ESI), simulation and design for manufacturability (DFM). This ensures a seamless transition to production without compromising speed or quality.

MGS engineers with decades of tooling expertise work early in the development process to identify defects and gain valuable insights.

What are the specific design principles or guidelines that MGS follows when customizing standard and modular tooling components for complex program needs?

Suxstorf: The goal when designing a Fast-Track tool is to closely simulate the critical features that ensure a successful production tool. The production tool design concept is determined before starting Fast-Track design. This enables the designer to incorporate key attributes into the Fast-Track mold.

During early supplier involvement, the team runs a part through mold flow simulations to identify risks and mitigations.

Critical features such as shrink rate, mold component material selection, gate location, gate size, cooling, ejection, venting and fit/function are incorporated into the Fast-Track tool. The process of design, build and mold sample expose any potential issues ahead of manufacturing multiple production cavities. This will help to minimize any rework or time delays when it comes to the production tool.

As we all have experienced, the cost of rework and time delays increases the further you progress into a program. Addressing potential issues during the part design, ESI process or tool design phase is the most cost-effective. In contrast, resolving issues during the validation or production phase of a program is considerably more expensive.

Can you provide more detail on how the Fast-Track Tooling Program integrates with early supplier involvement (ESI), design for manufacturability (DFM) and simulation to optimize tooling development?

Suxstorf: The Fast-Track Tooling is usually a single cavity to represent a multicavity tool. During the ESI process, the part is run through mold flow simulations to identify risks and mitigations. The Fast-Track tool enables us to gate, vent and eject the part just as it would in the multicavity production tool. This way we can test our risks and mitigation options before committing the dollars and resources to the production tool.

How does MGS ensure consistent quality and

The Fast-Track tool simulates production gating, venting and ejection, allowing risk testing before commitment.

performance during the transition from Fast-Track Tooling to full-scale production? Are there key steps or checkpoints during this process?

Suxstorf: We take a proactive approach to maintaining quality and performance as we transition from Fast-Track Tooling to full-scale production. From the very beginning, we design the Fast-Track tool while simultaneously working on the preliminary design of the production mold. This enables us to ensure the Fast-Track Tooling aligns closely with the production mold’s design intent, making the most of the insights gained during development.

To keep the process consistent and efficient, we assign the same mold designer, project manager and toolmaker to the project from start to finish. By keeping the team consistent, we ensure everyone stays on the same page, fully understands the project’s requirements and can address challenges seamlessly at every step. This streamlined, collaborative approach helps us deliver reliable results and a smooth transition to production.

What unique challenges does the Fast-Track Tooling Program address when working with materials used in the health care sector, particularly in terms of validation for flow, shrinkage, cooling and ejection processes?

Suxstorf: One of the most critical factors is gating. With our Fast-Track Tooling Program, we're able to use the same valve gate style, location and diameter that will be used in the production mold. This means that the parts we produce during development are much closer to what we’ll see in the final product, helping us move forward faster.

The program also enables us to quickly verify key aspects like tool construction methods using hardened steel, as well as the cooling systems and ejection methods. By validating these elements early on, we can shorten the engineering cycle, avoid delays and reduce the need for multiple tool grooming loops. Overall, Fast-Track Tooling enables us to streamline the process, reduce development time and ensure the parts meet the rigorous standards needed for medical applications.

Can you explain the role of MGS' global team of toolmakers in the Fast-Track Tooling process? How does their expertise contribute to meeting complex project requirements on a global scale?

Suxstorf: MGS’ global team of toolmakers plays a key role in the Fast-Track Tooling process, ensuring consistency no matter where the tooling is being developed or produced. Our project managers, toolmakers and designers all adhere to MGS’ global tooling standards. This enables us, for instance, to seamlessly design and build the Fast-Track platform at our European facility while producing the production mold at our U.S. site.

This global collaboration gives us flexibility and helps us improve timing, especially when a program is linked with an MGS Automation build which requires a large number of sample parts for testing. By tapping into the expertise of our global team, we can tackle the complex requirements of each project and deliver high-quality results efficiently across the globe. This structure not only streamlines operations but also makes the process more agile, enabling us to better meet the needs of our customers, no matter where they are.

Related Content

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreMold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

Read MoreTriple Threat: How One Shop's Success Resonates Across Three End Markets

When I revisited Eden Tool in New Freedom, PA, this past summer for a follow-up feature on this mold builder’s growth, I underestimated the story.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Mold Builder Looks for Opportunity; Leverages Network to Take on Challenges from Coronavirus

MGS Mfg Group looks at the opportunities the coronavirus presents and tries not to focus on the negative. This mold manufacturer believes in turning challenge into change.

Read MoreMGS Breaks Ground on New Innovation and Technology Center

Additional 120,000-square-foot facility bolsters headquarters campus with additional collaboration and innovation spaces for product development, tooling development, automation, and part and process validation.

Read MoreMGS Accelerates Customer Speed-to-Market By Expanding Fast-Track Tooling

MGS is expanding its innovative Fast-Track Tooling program to debut in the north American market. Designed to accelerate product development timelines and reduce costs for pharmaceutical, diagnostic and medtech companies, MGS' Fast-Track Tooling utilizes standard and modular designs and components that can be customized to meet complex program needs.

Read More