Software Update Enables Print Speed Improvement for Automated Toolmaking System

Mantle recently announced a software update to deliver performance enhancements to benefit moldmaking and injection molding customers.

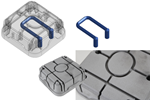

This complex injection mold core serves as an example of an insert produced using Mantle’s upgraded software which eliminates the need for sinker EDM. Source | MMT Staff

Mantle Inc., known for its automated toolmaking systems, recently announced a software update to deliver performance enhancements to benefit its customers. The update increases production throughput by up to 20% while introducing enhanced surface finish on downfacing surfaces. According to the company, it has increased adoption from leading moldmakers, injection molders and OEMs.

The technology offers a variety of benefits to transform toolmaking in terms of increasing production capacity as well as reducing lead times. The software update extends the company’s surface finish quality to downfacing surfaces and undercuts in molds, sliders and other complex tools. This upgrade enables manufacturers to create tooling components that can move directly to the molding stage, reducing the need for postprocessing to further cut down on lead times and labor cost.

According to Mantle, the automated toolmaking system accelerates product development and reduces time-to-market by expediting the delivery of First-out-of-Tool (FOT) parts. The technology enables companies to expand their toolmaking capacity during longer periods of skilled labor shortages. Manufacturers can optimize their existing workforce by automating challenging processes that would usually require manual intervention (while maintaining or even increasing production output).

The performance upgrade is currently available to all new and existing customers as an over-the-air software update.

Related Content

-

Best Practices for Hitting Critical Numbers: Communication and the Shrinkage Factor

Start with an upfront review, discussion and collaboration with the customer and then consider the shrinkage factor.

-

Plastic Injection Molding Starts with the Pellet

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

-

What Is Design for Manufacturing? Part 1 of 4

A DFM review ensures part design meets injection molding standards, enhancing cycle time, yield and aesthetics. Here are key considerations for the review.