Same Great Content, Smarter Delivery: What's Next for MMT

MMT is moving to six print issues a year and ramping up our digital game so you get more content, faster.

Since 1998, we've been your go-to source for moldmaking know-how, delivering practical insights through our monthly print magazine. As we head into 2026, we're making a change to better serve you — shifting from 12 issues to six print editions per year.

I could cite financial pressures in the industry or the changing media landscape, but here's what really matters: You're not losing content. In fact, you're getting more of it, delivered more frequently through channels that work better for how you consume information today.

Let me explain. When we launched nearly three decades ago, moldmaking barely registered on trade media's radar. MMT filled that gap and quickly built strong support from suppliers committed to this manufacturing niche. Back then, creating a monthly magazine that served most readers was straightforward. The industry looked different. It was more cohesive, more predictable. Today's reality is a bit messier. Consolidation has reshaped the moldmaking landscape. Veteran mold builders are retiring. A new generation is entering the trade with completely different media habits. Cramming everything everyone needs into one monthly issue? It's no longer the best way to serve you.

So we're leaning into digital. Fewer print issues means we can invest more into our website, e-newsletter, social media and video content to help deliver timely updates on technology, applications and industry news as it breaks, not weeks later. And our live events and webinars? Those will continue as usual. Just sign up for our MMT Today newsletter to stay in the loop.

The bottom line: Same commitment to practical moldmaking insights you've trusted since 1998. Smarter delivery. More frequent updates. Higher quality across every channel.

One more thing: MMT has always covered both the technology and business

of moldmaking because we know many of you wear both hats. You're running toolrooms and making strategic business decisions every day. That's why I'm excited to tell you about Manufacturing Connected, a new platform from our parent company, Gardner Business Media. It delivers actionable insights on advanced manufacturing technologies, additive manufacturing, automation, sustainability, business leadership, workforce development — the big-picture issues facing manufacturing leaders today.

“Gardner’s legacy brands dive-deep into their subject matter, whether that’s CNC machining, moldmaking or composites fabrication,” says Stephanie Hendrixson, editor-in-chief of the new brand, in addition to her continued role with Additive Manufacturing Media. “But the reality is that all manufacturers are contending with similar issues and each vertical that we cover can learn from the others,” she explains. “Manufacturing Connected is a process-agnostic platform designed to inform the leaders who need that broad, cross-disciplinary insight to grow their businesses.”

“We’ve launched Manufacturing Connected on a simple premise: the best solutions in manufacturing often come from looking beyond your own process or market,” says Rick Brandt, GBM market vice president, advanced manufacturing group. “By connecting the dots across technologies, industries and proven practices, we’re helping manufacturers move faster and smarter.”

Intended for business owners, C-suite executives and other decision makers, Manufacturing Connected offers that insight through short, two-minute reads presenting key takeaways, coupled with in-depth interviews and reporting from GBM’s experienced B2B journalists.

The introduction of this platform includes the launch of Leaders in Industry, an interview series for time-strapped C-level professionals that zeroes in on a specific challenge, trend or opportunity to deliver actionable insights viewers can implement in their businesses. I’ll be hosting these interviews and I’m excited to sit down with the people who are actually in the trenches, leading transformation on the shop floor and in the C-suite.

If this sounds like you, check us out at www.MFGConnected.com and subscribe to the weekly newsletter here.

Last but not least, if you have a specific topic you’d like covered in Manufacturing Connected reach out to me at cfuges@gardner.media.

Thanks for being part of this journey with us.

Related Content

PLASTICS Voices Tariff Concerns, Support for Trade Policies to Bolster US Manufacturing

PLASTICS is urging U.S. policymakers to support balanced trade policies that enhance U.S. competitiveness, reinforce supply chains and drive continued innovation.

Read MorePTXPO 2025: Mold Builders Showcase Innovation, Automation and Efficiency Across the Supply Chain

Mold manufacturers highlight advanced machining, automation, precision molding and validation technologies driving speed, quality and efficiency across tooling applications.

Read MoreReshoring Initiative Launches Nationwide Reshoring Survey

The nationwide reshoring survey aims to glean factors that are affecting manufacturers’ decisions on whether to reshore factories and supply chains. The survey is open through March 15, 2025.

Read MoreNavigating Economic Resilience and Consumer Trends

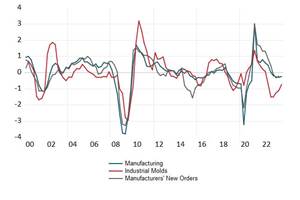

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read More