Micro-Diameter End Mill Series Reduces Cutting Time, Enhances Finishing for Ultra-Precision Moldmaking

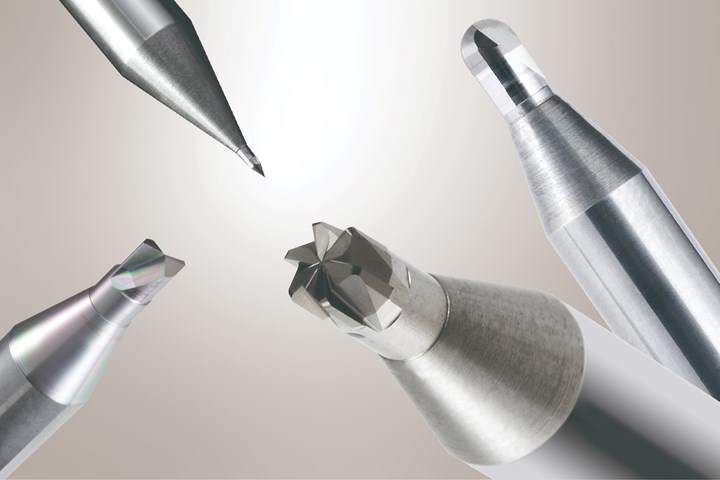

Towa Corp. features CBN and proprietary-coated solid carbide end mills that feature high accuracy, optimized sharpness and wear resistance and ensure long tool life.

Established in 1979, Towa, with headquarters in Kyoto, Japan, is a global manufacturer of ultra-precision molds and molding equipment for the semiconductor industry. Through the manufacture of ultra-precision molds, Towa has developed its own line of micro-diameter end mills and drills that feature high accuracy, with excellent wear resistance, sharpness and long life. Towa is now introducing its end mill product line to the North American market.

The end mills, tipped with CBN, which is the second hardest material after diamond, are offered in sizes ranging from 0.1-6 mm in diameter, with various configurations — from sharp corner, radius corner, ball, standard neck length and extended neck length. Towa also offers CBN end mills in multi-flute configurations. By maintaining the same feed per flute, and increasing the number of flutes, the company notes reduced cutting time, and thus, increased profitability. As the result of their hardness, the CBN series of end mills are idea for machining hardened materials in the range of 55 to over 60 HRC.

Towa’s proprietary-coated solid carbide end mills are offered in sizes ranging from 0.1-20 mm in diameter, and with the same configurations as the CBN series. Specialized coatings, such as “Hard Star” is designed for finishing operation for harden steels from 55 to over 60 HRC. “Ion Depo” coating enables the machining of hardened steels to the 50 HRC range, and is well-suited for machining non-ferrous materials such as copper and aluminum alloys and graphite.

Towa is also able to customize end mills with specific sizes and geometries to fit user applications.

Related Content

-

How to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

-

Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

-

Drill Tailored to Challenging Materials Like Stainless Steel and Titanium Drilling

Guhring Inc. highlights the RT 100 InoxPro, a cutting-edge solid carbide drill tailored specifically for challenging materials like stainless steel and titanium alloys.