Hydraulic Mechanical Quick Mold Change for Aluminum Molds

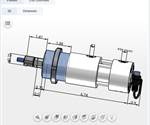

The PFA Hydra-Jaws QMC system replaces common mechanical clamp systems and through bolt fastening methods with an easy-to-operate hydraulic mechanical clamping system.

Photo Credit: PFA Inc.

PFA Inc. offers a quick mold change (QMS) system ideal for non-magnetic mold clamping with consistent force and mechanical clamping advantages.

The PFA Hydra-Jaws QMC system replaces common mechanical clamp systems and bolt-through fastening methods with its flexible hydraulic mechanical clamping system for use with a variety of mold base dimensions and base materials.

Shops can now more quickly change out molds with insulator plates, non-magnetic materials such as aluminum, and rough or uneven surfaces in support of Single Minute Exchange of Die (SMED) programs. Shops using mechanical clamping systems also have minimal maintenance needs.

The hydra-mechanical clamp design allows hydraulic pressure to perform consistent force clamping. This function ensures that equal pressures and known clamp tonnage is applied to the mold. After clamping, operators easily spin locking nuts on each clamp to the clamp body, securing the clamp mechanically at tonnage. They can then remove hydraulics with the clamps mechanically securing the mold to the platen.

Made-to-size bolt-on platen plates with boomerang-shaped slots are commonly requested; however, systems are available to match a variety of needs, including multiple slotted plates, single-side clamping, and in-machine platen slots.

Related Content

-

Technology Review and Sourcing Guide 2025: Mold Materials

Building a high-quality mold begins and ends with the proper selection of appropriate mold materials. Tool steel, aluminum, copper and alloys are a just a few you can find in this exclusive, online-only content that includes a supplier list for mold materials.

-

Debunking the Myths: Aluminum Tooling Facts vs. Fiction

Advancements in aluminum alloys, machining and design debunk myths, proving aluminum molds deliver durable, precise, high-quality and cost-effective production solutions.

-

Five Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.