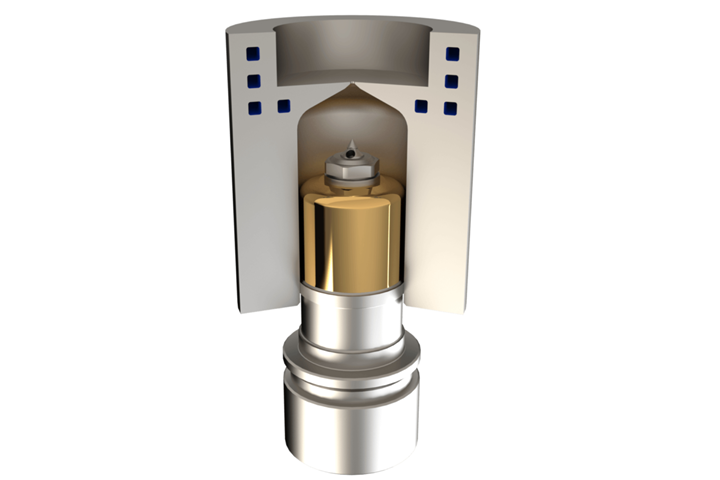

HTS International Optimizes Conformal Cooling with iTherm Technology

Amerimold 2021 exhibitor HTS introduces iTherm for injection molds, which can be integrated through any toolshop with various options for manufacture.

Photo Credit: HTS

HTS iTherm, which can be integrated through any toolshop, with various options for manufacture, offers conformal cooling for injection molds, improving the ability to cool challenging inserts and cores, and often reducing cycle time or improving part quality. Material options include H13, 420SS and other standard tool steels.

Example components will be on display at Amerimold this September, where attendees can consult with expert engineering staff about design solutions for improving their tooling.

Exhibitor: HTS International Corp.

Booth M-929

Related Content

-

5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling, and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.

-

Descaling Systems Eradicate Debris in Cooling Passages and Water Lines

Distributed by PCS Company, Goodway portable descaling units remove scale, mineral, rust and grime from cooling passages and water lines, which can be within hot runner systems and injection or die cast molds.

-

How to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.