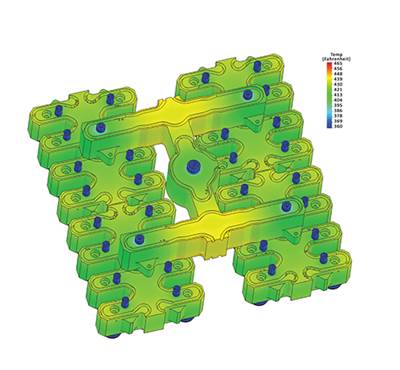

A premium household appliance cover is an over-molded part that previously had a high scrap rate due to sink issues caused by the gate freezing before the part could be packed. After implementing heat-inject technology, the material flowed freely through the fan gate, allowing for proper packing of the part. This process eliminated sink issues and reduced scrap.

Heat-inject technology enhances the surface quality of a part and improves cavity filling by controlling the mold temperature with targeted heat pulses. This method effectively reduces weld or knit lines that often appear around holes and openings in a part. It also improves melt flow in hinges, thin walls, delicate geometries, microstructures and through cold runner fan gates and the thin-walled sections of the cavity.

Without heat-inject technology, knit lines develop on the backside of each hole.

Until now, fast mold part surface heating utilizes induction heating, which requires 480 VAC, a three-phase power supply that draws a very high amperage. In contrast, heat-inject technology is low voltage and amperage conduction heating.

Heat-inject technology is designed as an add-on module for unitized manifold systems. It features a simple design and is easy to install, eliminating the need for extensive mold modifications and reducing the costs associated with alternative solutions for surface defects. It also has low power consumption, requiring only a 220 VAC, single-phase, 30-amp power input.

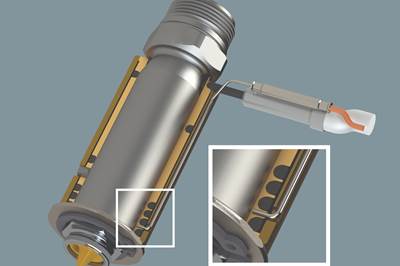

Unlike traditional heaters, heat-inject technology operates using a patent-pending Z-system. Rather than being an additional component integral to the mold heater, it functions as a movable tempering stamp with a heated tip. This stamp introduces a heat pulse by briefly pressing against the rear wall of the cavity, effectively making weld lines and flow lines invisible on the surface.

The heat stamp is a 240 VAC low-amp heater, thermocouple monitored and controlled by a temperature and actuation controller using heat-inject technology. The heat stamp is always heated to a high temperature.

The mold features a machined cutout specifically designed for the heat stamp, positioned at a predetermined distance from the cavity.

Also, a thermocouple located within the mold cutout monitors the temperature of the surrounding mold steel and sends this information back to the heat inject controller.

The actual temperature of the mold steel is displayed, and a graph of temperature vs. time is used. The desired temperature is typically achieved in under five seconds. The heat stake retracts, usually before the injection process.

Any plastic injection-molded part with aesthetic requirements located opposite an opening, or where flow fronts collide in corners, is a candidate for consideration. Additionally, any part that is difficult to fully pack due to the fan gate melt freezing prior to packing the part is an excellent candidate.

Related Content

Initial Pellet Contact is the Screw

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: the machine’s reciprocating screw, which is often misunderstood and applied to the process incorrectly.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreHow to Overcome Five Common Hot Runner Cable Connection Problems

Here are some simple solutions for pushed-back or bent pins, pushed-back inserts, high amp deterioration, loose or broken latches and missing or loose ground wire connections.

Read MorePlastic Injection Molding Starts with the Pellet

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreRead Next

Troubleshooting "Actual" Hot Runner Controller Temperature

The root cause of a recent part defect was suggested to be the delivery of a melt that was too hot. The true root cause, however, was something else entirely.

Read MoreReduce Part Failure with Melt Delivery Science

The best way to determine when naturally balanced, rheological managed and thermally balanced hot runner solutions are required as a single solution is to examine the science behind each approach.

Read MoreVIDEO: Hot Runner Solutions Driven by Performance and Partnership

INCOE’s New Business Development Manager Jim Bott and Business Development Manager David Shirley break down valve gating technology, balanced hot runner systems and the secret to partnering with customers to develop the right melt management technology.

Read More