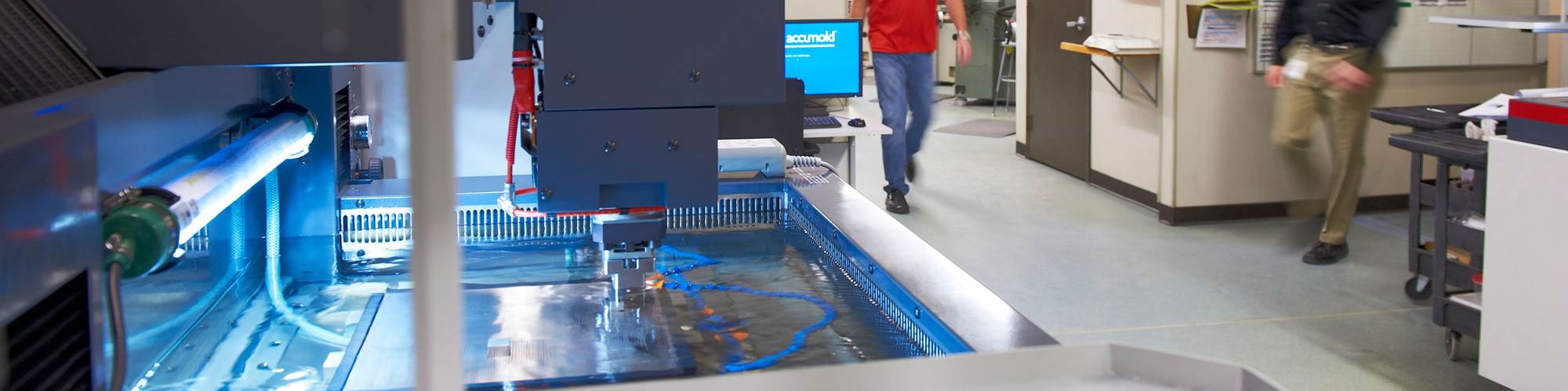

There are unique issues in micro mold fabrication. The ability to design a tool with these in mind, and also to validate the integrity of the finished micro tool before production, are vital to the project success. Photo Credit: Accumold.

Metrology is an enabling technology and today’s options provide invaluable insight concerning the demands of micro-size tooling and parts. Metrology equipment and skills are used to measure steel details in the mold, part features/dimensions to ensure the parts meet print tolerance and to guarantee a capable process.

Typically, shops use high-end optical white light interferometer-based metrology systems to validate parts and vision systems to analyze and validate the intricacies of the steel micro molds. The use of such metrology equipment and expertise can provide data and immediate feedback that helps to determine if steel in the mold is acceptable, or if adjustments are required.

The importance of metrology and validation in micro moldmaking is in large part due to specific contingencies that exist in this niche of the industry that can impact design parameters and, ultimately, the integrity of the finished tool and finished part.

Four issues of concern are gating, ejection, mold splits and direction of pull.

1. Ejection & Gating: Ejection or gating is often ignored as parts get smaller, but must be considered if you want to optimize the mold build process. For example, having a small ejector pin on a thin and deep feature can make burning a start hole difficult or impossible, or gating in a thin area when there are other thick areas on the part can cause non-fill and sink.

Also, when planning gating and ejection, anticipate some gate vestige or flash. This preparation during a mold split decision can turn a simple tool build into a very complex one, or it can turn a mold that was going to be very difficult to run into one that runs exceptionally well.

Micro molding involves extremely small parts with exacting tolerances, so the importance of validation and metrology is vital.

2. Split Lines: Changing an ideal split line can cause unforeseen consequences to the mold. For example, a slide with a large surface area may cause injection pressure to flex the mold. A shutoff in the direction of pull will provide a more robust shutoff.

The direction of the clamp holds a shutoff together as a direct result of clamp tonnage. However, a slide is a factor of the tonnage reduced by the heel angle and strength surrounding mold steel.

3. Feature Size: Part design can significantly impact electrode manufacturing. For example, if there is a square counterbore with sharp corners, you may need four different electrodes to create the feature. If the part had radii added at the corners, this might be possible using only one electrode.

When it comes to ensuring a part will release from the cavity, consider draft, especially when dealing with very small features. Draft is often an oversight with small parts because the amount is so small.

4. Assembly: Part assembly is an important consideration when optimizing the final part and simplifying the tool build. When building a mold, it’s easy to think that you must machine everything exactly to size. However, sometimes it is better to add clearance to minimize the number of areas that require accuracy.

Adding clearance enables the mold builder to use a less accurate method for certain parts and leave the accurate machining for areas where it is necessary, which saves time. Clearance on the molded parts can be approached the same way.

Micro molding involves extremely small parts with exacting tolerances, so the importance of validation and metrology is vital. There are specific issues that are unique to micro mold manufacturing, and the ability to design a tool with these in mind and also to validate the integrity of the finished micro mold before production are vital to a project’s success.

Related Content

Tooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MorePlastic Injection Molding Starts with the Pellet

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

Toolroom Perspective on Micro Molding

Design for manufacturing, or more specifically design for micro molding is critical to this mold manufacturing niche as it presents unique challenges and impacts the tool build.

Read MoreOpportunities for Mold Shops with Micro Molds and Micro Milling

Learning about the trends and challenges with micro molds and micro milling will help shops maintain their competitive edge.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More