Face Shield Safeguards Against Machining Equipment

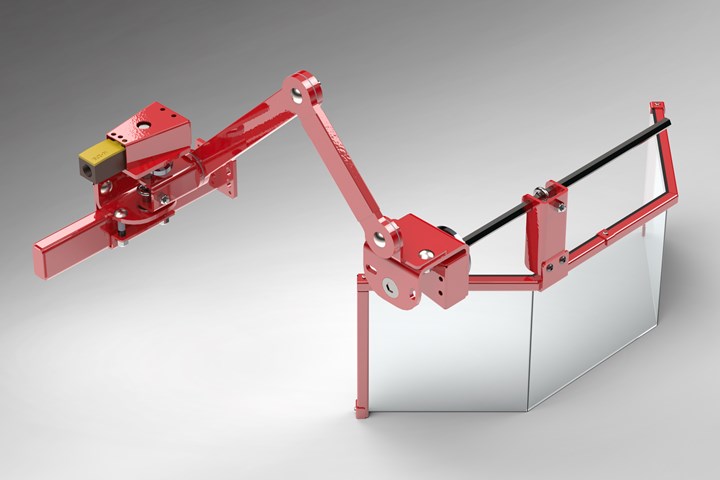

The Rockford Systems’ Protector Shields defends operators from flying debris, lubricants, coolants and swarf from cutting and turning machines.

Photo Credit: Rockford Systems

Rockford Systems’ Protector Shields safeguard against mills, drills, lathes, grinders and other cutting and turning machines. Constructed of 14-gauge, powder-coated steel and thick 3/16” shock-proof, scratch-resistant polycarbonate, Protector Shields are said to defend operators from flying debris, lubricants, coolants and swarf. An LED light incorporated into the frame also illuminates the work area for improved visibility; some models may feature color-changing options, to help indicate when the shield is open or closed.

For additional protection, an interlock will disengage power and prevent a connected machine from starting up when a Protector shield is not in the correct work position. An optional safety monitoring relay can also be added to monitor the interlock switch for failure or damage.

Rockford Systems’ Protector Shields Series are modular in design so that shape, size, mount, arm, offset, lighting, interlocking and safety monitoring can be configured according to specific machine needs.

Related Content

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.