For many scientific or decoupled molding has become the gold standard for delivering consistent, high-quality parts, especially as industries demand tighter tolerances, advanced geometries and greater traceability. However, the key to successful decoupled molding does not start at the press, but on the bench — during mold design.

Here are four intentional mold design choices that can unlock the full benefits of Decoupled Molding Levels 1, 2 and 3.

1. Venting

In decoupled molding, particularly at Levels 2 and 3, fast fill rates and pressure-controlled transitions create significant gas displacement. If that gas has nowhere to go, it leads to burns, shorts or inconsistent cavity filling.

To avoid this, consider adding venting at end-of-fill locations and thin-walled

areas, maintain tight tolerances in vent depth (typically 0.0006"-0.001") and use ejector pin venting and porous inserts in high-risk zones when designing the mold. Also, remember that in high-cavitation molds, balance venting equally across cavities to prevent overpacking or underfilling during the switch from fill to pack.

2. Gating

The gate controls how material enters the cavity and how it responds during velocity-to-pressure transitions in Level 2 or pressure-based switchover in Level 3. Improper gating creates pressure drops, shear, hesitation or flashing.

To prevent these effects, use gates sized for high shear rates but smooth transitions, place gates to promote uniform fill paths and avoid abrupt direction changes that disrupt flow behavior. For Level 3, use symmetrical gate design to improve cavity pressure consistency and sensor alignment.

The most sophisticated processing strategy will fall short if the mold isn’t engineered to support it.

3. Cooling

Decoupled molding relies on repeatability. Even the best switchover logic can’t compensate for a mold that heats unevenly. Cooling must be efficient, uniform and stable, especially in multi-cavity tools or thin-walled parts.

With this in mind, prioritize turbulent flow in water lines, use baffles and bubblers to reach tight spots and integrate conformal cooling where appropriate. Consistent cooling reduces cycle variation, which improves sensor reliability and process window robustness.

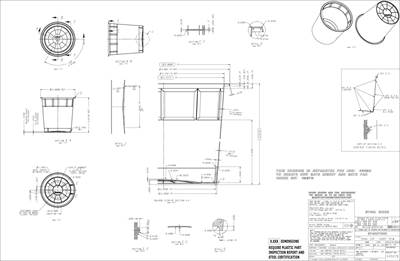

Level 3 decoupled molding depends on precise, well-planned sensor placement to deliver accurate cavity pressure feedback and true closed-loop control. Source: Molded Precision Components

4. Sensors & Validation

Level 3 decoupled molding is built around real-time cavity pressure feedback. To achieve true closed-loop control, sensors must be placed where they’ll provide usable, accurate data and the mold must accommodate their installation without compromising steel integrity.

For a successful outcome, plan sensor locations during the design phase, not after. This includes routing wiring channels internally to protect from heat and wear and includes access panels or windows for calibration and service. In addition, remember to use the sensor data in both initial validation and long-term quality monitoring. It’s not just about control — it’s about traceability.

From venting and gating to cooling and sensors, every design choice is a lever for performance.

At its core, decoupled molding is about control — separating fill from pack and using data to drive repeatability. But the best process strategy in the world can’t overcome poor mold design. Moldmakers should be an integral part of every scientific molding conversation.

Related Content

Play the Moldmaker Card Game at PTXPO 2025!

Think you’ve got what it takes to be a top moldmaker? Put your skills to the test with the Moldmaker Card Game. Dust off your decks from previous years or stop by PTXPO Booth 1235 to grab your own!

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreStrategic Mold Venting – Placement and Method

Knowing where and how to vent a mold is critical for difficult areas and complex geometries.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

Tooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreCollaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

Read More