Cycle time can significantly impact the profitability of a project. When considering the challenges that high-temperature thermoplastics pose for consistently producing parts that meet tolerance requirements, the complexity of profit margins increases. Temperature control has long been used to help mitigate these issues; however, what happens when the areas that need cooling are located deep within a mold cavity?

Jet Cooling Origins

One notable technology to address this challenge was developed in Japan about 25 years ago. “Jet cooling is an advanced technique that improves cooling in die casting by addressing critical areas where cooling is typically insufficient. This method involves gundrilling deep into one or more core pins in the die where cooling is critical but nonexistent. A jet cooler is then inserted into these drilled core pins and connected to a jet cooling machine,” explains Mark Steen, general manager of Lethiguel USA in Minneapolis, Minnesota. Lethiguel USA is part of the Lethiguel Group based in France, which develops, manufactures and supplies thermal solutions to optimize manufacturing processes, including jet cooling.

Water lines are connected to the jet cooler, enabling high-pressure water to be injected into the individual core pin cavities. Once the injection phase is complete and the material begins to solidify, the jet cooling machine sends high-pressure water into the core pins. This process cools the area quickly and more evenly, ensuring that the inner portions of the part cool down immediately.

“One of the main issues that jet cooling addresses in die casting is the reduction of shrink porosity away from the core, which helps maintain the integrity of the part. It also reduces cycle times — all of which are important to plastic injection molds as well,” Steen says.

Adapting Die Cooling Insights for Mold Applications

As the automotive industry continues to focus on reducing the weight of vehicles, components originally made of steel are being redesigned in aluminum, and then further transitioned to plastic. G.A. Roeders, based in Germany, operates both plastic injection molding and high-pressure die-casting divisions. Although both processes involve injecting a liquid material into a mold to create a finished component, the higher temperatures required for aluminum die casting have led to different innovations.

Recognizing the advantages of jet cooling in its aluminum die-casting division, G.A. Roeders initiated trials using this technique on thermoplastic parts that had been problematic — specifically, high scrap rates and extended cycle times that were adversely affecting profitability.

“For some of the parts we were molding, our profit margins vanished and we needed to find a solution. Given that jet cooling has proven effective in high-pressure die casting, a similar process, we believed it could also be beneficial for plastic injection molding,” says Andreas Roeders, general manager of G.A. Roeders.

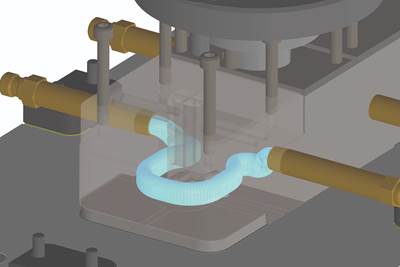

Jet cooling uses pulsed air and water to efficiently cool core pins, optimizing cycle times and ensuring consistent mold temperature control. Source | Lethiguel

How It Works

The operation of a jet cooling machine begins with the injection phase of the molding machine. Once the mold is filled with plastic, a combination of air and water is pulsed into the core pins to aid in cooling the component. Through thermal analysis, the cooling duration for specific areas within the die can be adjusted across all four channels, enabling efficient cooling of up to 32 or more core pins.

Once the part has cooled adequately, the water pressure cycle is stopped and compressed air is directed through all of the core pins to remove any remaining water. The water is then recirculated into a holding tank via a closed-loop system in the jet cooling machine, where it is cooled again through the heat exchanger integrated into the tank.

Water Quality

Maintaining water quality is crucial, so it is essential to test the water to ensure the mineral content is optimal, which typically involves softening the water. Significantly reducing calcium levels enhances the cooling efficiency of the water used in the process.

“Even a buildup of 0.005 inches of calcium can decrease cooling efficiency by as much as 40%. If a reliable water source is unavailable, installing a softening resin tank on the water inlet can help keep the mineral content low,” Roeders says.

Despite high-quality water, there is always a risk of water lines becoming clogged, which can hinder the proper cooling of the core pins. Small chips from manufacturing the tooling and other debris can enter the closed-loop water system and eventually build up in a jet cooler. According to Roeders, “Using an additional system with sensors to monitor water flow introduces an element of predictive maintenance, because it tracks the decline in water flow over time. The system can also issue an immediate critical warning if large debris blocks a cooling line suddenly.”

Machine Maintenance

Overall maintenance is straightforward. The main steps include draining the water tank every couple of months and rinsing the interior through a hatch located on the back of the unit. After completing these steps, refill the tank with softened water to ensure that water with minimal hardness flows through the die.

Also, there is a main filter on the back of the machine that should be removed, inspected and cleaned every few weeks. To help ensure these maintenance tasks are performed, the unit is equipped with sensors which monitor the conductivity of the water in the tank and the pressure in various key areas. These sensors will alert you when maintenance issues need to be addressed.

By significantly reducing cycle times, molding machines become available for other projects, increasing opportunities for bidding and winning new contracts. Also, reducing the scrap rate by addressing dimensional issues related to cooling can positively impact the bottom line.

Jet Cooling In Action: Three Examples

Thermoplastics — such as the PA Polyamide Series, Polybutylene Terephthalate (PBT) and Polyoxymethylene (POM) as well as high-performance thermoplastics like Polyetheretherketone (PEEK) — are excellent choices for jet cooling due to their high-temperature resistance, according to Steen. This is particularly beneficial for thick-walled components and areas deep within the part, where traditional temperature control methods, such as water jackets, may not reach effectively.

1. Suspension System Valve Housing — Material: Grivory HTV 5 H1

A valve housing, which is responsible for controlling a vehicle's suspension system compressor, weighs 220 grams (7.8 oz). It has encountered several issues, including a long cycle time caused by excessive wall thickness of up to 8 mm. Additionally, the housing suffers from leaks due to shrinkage and warping, which are attributed to inadequate heat dissipation, particularly in the contour core that measures 4 × 82 mm in length.

Initially, jet cooling was implemented in two cores, which reduced the cooling time from 84 seconds to 57 seconds. By extending jet cooling to additional areas, bringing the total to 11 cores, the cooling time was further decreased to just 22 seconds. This modification resulted in an overall cycle time reduction of 40%.

The core temperature was lowered from 232°C (450°F) to just 112°C (234°F). This more uniform temperature resulted in several benefits, including more dimensionally stable parts, reduced shrinkage and no component warpage. Also, there was a significant reduction in cycle time. With more than 500,000 pieces being delivered annually, the savings in both time and scrap were substantial.

Jet cooling reduced valve housing cycle time by 40%, improved dimensional stability, minimized shrinkage and eliminated warpage, enhancing production efficiency. (Top images) without jet cooling and with jet cooling. (Bottom images) contour core 4-mm thick and 82-mm long. Source (all images) | G.A. Roeders

2. Park Release Valve — Material: Ultradur B 4030 G6

A park release valve, weighing 231 grams (8.1 oz.), experienced several issues that contributed to high cycle times and elevated scrap rates. These problems included a long cycle time caused by excessive wall thickness, warping due to heat dissipation and the presence of four long core pins within the valve.

With this part, the focus was on the central core, specifically by gundrilling four jet coolers into this area to remove heat quickly and efficiently. As the plastic cools in the central core, the thicker walls of plastic from the three outer features of the casting also decrease in temperature. This process results in reduced shrinkage and prevents warping of the part. Overall, the cycle time was reduced from 101 seconds to 80 seconds, which represents a 20% decrease for the 220,000 pieces shipped each year.

Jet cooling using four jet coolers (left) cut the cycle time to produce a park release valve (right) by 20%, reducing shrinkage, preventing warping and improving efficiency for 220,000 parts annually.

3. Piston for Air Suspension Compressor — Material: Grivory HTV 5 H1

Despite being a very light and small component, weighing only 14 grams (0.5 oz.), the cycle time was substantial for this piston. With a requirement to produce over 1.4 million pieces annually, there was a clear opportunity to tackle the long cycle times and warpage caused by inadequate heat dissipation.

To efficiently cool the plastic, the solution involved drilling directly up the center of the core. As a result, the overall cycle time for producing the part was nearly halved, dropping from 33 seconds to 17 seconds. Similar to other parts made using this method, there was reduced shrinkage and no warping.

Jet cooling halved the cycle time to produce a piston (left) using one jet cooler (right), reducing shrinkage and eliminating warping, ensuring efficient production of over 1.4 million parts annually.

Cooling Success

Through a process of trial and error, along with collaboration with Lethiguel, G.A. Roeders successfully eliminated issues related to shrinkage, warpage and dimensional inaccuracies that were resulting in higher-than-normal scrap rates. “The solidification time also improved significantly, reducing cooling cycle times up to 50%,” Roeders says. For manufacturers producing high-volume parts across various industries, these improvements can translate into substantial time and material savings.

By significantly reducing cycle times, molding machines become available for other projects, increasing opportunities for bidding and winning new contracts. Also, reducing the scrap rate by addressing dimensional issues related to cooling can positively impact the bottom line.

“With our experience in transferring jet cooling technology from high-pressure die casting to plastic injection molding, we are confident in bidding on projects that others may find challenging. We have established a proven method to reduce cycle times and minimize scrap rates for high-temperature plastic components. Jet cooling offers us a significant competitive advantage and has become a regular part of our processes for both aluminum and plastic,” Roeders says.

Related Content

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

Read MoreThe Lowdown on Guided Ejection Systems

Learn more about guided ejection systems in terms of when, where, how and why to use them to benefit you as the moldmaker. Use this guide to better understand best practices associated with guided ejection systems.

Read MorePhysics of Side Actions: An Introduction to Elasticity and Thermal Expansion

Material elasticity and thermal expansion critically determine mold design performance and troubleshooting effectiveness.

Read MoreHot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

Read MoreRead Next

Strategic Mold Cooling: Optimizing Molding Quality and Cycle Efficiency

Proper cooling is crucial in molding, yet often overlooked. Discover proper cooling methods to prevent defects and improve efficiency.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreStrategic Mold Cooling – Hot Spots

With complex plastic parts it can be difficult to deliver proper cooling to all potential hot spots. Here are strategies to help cool some difficult-to-cool areas.

Read More