Case Study

Workflow Automation Transforms Moldmaking Operations

Legacy Precision Molds implements JobTraQ’s no-code workflow automation software to better coordinate complex production tasks across departments, improving efficiency, tracking and decision-making.

Read MoreContinuous Wave Laser Technology Improves In-House Mold Maintenance Capabilities

International Inc. integrated American Laser Distributors’ 2,000-Watt Laser Cleaner for in-house mold cleaning, resulting in time and cost savings.

Read MoreAutomated Grinding Machines Yield Tighter Tolerances and Save Resources

National Tool & Manufacturing Co.’s integration of two Ziersch grinding machines into its shop floor enables the tight tolerance demands from its customer base and simultaneously frees up manual resources for other projects.

Read MoreUsing a Simulator to Support Upskilling and Empowering Workers

A virtual machine tool trainer powered by digital twin technology helps bridge the labor gap, starting with school programs.

Read MoreReal-Time Mold Monitoring Boosts Molding Efficiency and Cost Savings

FloControl software integrates with existing mold design tools, offering real-time tracking and optimization from design to production, enhancing efficiency and reducing costs for ProPlastics.

Read MoreHow 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its business — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

Read MoreDeep-Cavity Cooling Made Easy

G.A. Roeders uses an advanced cooling system employing gun drilling to deliver high-pressure water to quickly and evenly cool areas deep within a mold cavity.

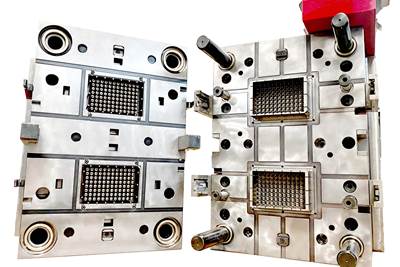

Read MoreHot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

Read MoreAdvanced Mold Monitoring for Efficiency

ITW Body and Fuel optimizes mold performance through real-time monitoring and integrated asset management, achieving significant reductions in downtime, scrap rates and maintenance costs.

Read More3D Printing Accelerates R&D Process For Prototyping Molds

Utilizing Axtra3D’s additive technology, LSI Solutions, a medical equipment manufacturer found the compatible machine it needed to accelerate its R&D process for prototyping molds for medical devices.

Read More