Century machine operator David Hawes sets the tooling on the spindle of the Zimmermann machine. Source (all images): Zimmermann Inc.

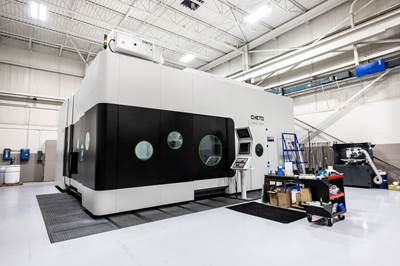

Zimmermann Inc. has successfully installed and commissioned its FZU37 portal milling machine at Century Tool, a leading tool and die manufacturer located in Fenton, Michigan, which is part of the Tooling Tech Group. Century manufactures a lot of large tools for compression molding of composites and other substrates for a variety of industries, including automotive, heavy truck, off-highway, agriculture, power sports and even infrastructure like water tanks. They specialize in Class-A exterior body panels, so the surface finish is critical.

The FZU37, with a workpiece capacity of 5m x 4m x 1.5m, has already demonstrated its value. Tom Bradford, the customer’s Director of Manufacturing, remarks, “The table size, speed and accuracy have already increased our capabilities by 30% or more.”

“During the very long runs we do on the Zimmermann, maintaining tight tolerances is key, and the machine, plus its onboard control technology, make that happen for us.”

Both Bradford and the machine operator, David Hawes, highlight the advantages of the Heidenhain TNC7 control system. This is one of the first machine tool installations in the US featuring this advanced CNC technology, which plays a crucial role in production planning, CAD/CAM integration, cycle performance and data logging. The CNC is also equipped with a visual simulator for the cutting path, which aids in cycle validation and in-process monitoring.

Cornelius Kiesel, President of Zimmermann, states that his company was

Typical molds at Century, made from steel or aluminum, are used in compression molding various materials for structures used in automotive, off-highway, consumer durables and more.

approached to discuss a new machine that would replace an existing smaller machine that was no longer operational, as well as expand the capabilities of other machines on the floor at Century. “We determined the specifications for the new machine and outlined its tasks for both finishing and semi-finishing. The primary goal was to significantly reduce the number of hours required for these processes on the very large workpieces at Century, while still enabling them to perform the roughing process using their existing equipment.”

“To simplify the process, we chose the FZU37 machine, allowing us to fill the foundation of the replacement machine to be flush without needing significant foundation modifications. After several discussions and a few adjustments to the accessories, we finalized the layout. These improvements enabled us to expand the dimensions to a total travel of 5000mm x 4000mm x 1500mm (197” x 157” x 59”), representing a 79% increase in travel within the same floor space. The FZU37 was then ordered with a state-of-the-art specification suitable for an advanced machine shop like Century, which includes features such as our tool changer, top cover, mist extraction, high-pressure coolant, tool laser and touch probe. Century Tool also aims to upgrade their control system to the new generation Heidenhain TNC7,” Kiesel explains.

Lastly, Kiesel explains, “Zimmermann also integrated an extended spindle housing for deeper cavities, raised the side walls to provide sufficient clearance and reinforced the machine table to handle the challenging molds our customer expected to produce on this machine. Once all these machine parameters were finalized, we completed the machine quickly, commissioned it, conducted onsite training and assisted Tom and his team in the startup process.”

Tom Bradford and David Hawes of Century review a cycle setup on the Heidenhain TNC7 CNC on the Zimmermann machine. This portal milling machine is among the first in America with this advanced CNC onboard. The cycle can be fully simulated before running.

Tom Bradford acknowledges Alfio Campagna, the project manager for Zimmermann, for his crucial support in getting the machine into production at Century. This was the first Zimmermann portal mill purchased by the moldmaker.

Bradford praises the Heidenhain team for providing three days of training on the CNC at their facility in Chicago, followed by two additional days of onsite training at Century. Operator Hawes mentioned that he had extensive experience with Heidenhain controls, which allowed for a quicker training process. However, he notes that the new control system includes many innovative features, such as Smart Programming—a graphical programming tool that enables users to draw contours directly on the touchscreen. The CNC then converts these designs into Klartext (German for "clear text") programs. Century primarily uses Visi as its CAD software and Tebis for CAM. Bradford says the integration of these programs with the onboard CNC software was seamless, which streamlined the configuration of programs and posts, resulting in a smoother startup and operation.

The new CNC machine includes a Component Monitoring feature that protects the spindle bearing from overload and detects increased wear in the drive train while the machine operates. This feature provides valuable data for predictive maintenance and assesses the machine's process capability. This capability is crucial for Century, which exclusively uses the Zimmermann machine for large, one-off mold preparation, often removing over 90% of the material from a workpiece over several days of machining.

Cornelius Kiesel, President of Zimmermann Inc., Brian Czapla, Director of Sales at Century, Yousif Sallan, Project Manager at Zimmermann and Tom Bradford, Director of Manufacturing at Century, with the FZU37 portal milling machine.

The CNC machine's ergonomics are highly user-friendly. The screen layouts and touchpad controls can be customized to meet individual user preferences. Also, symbolic gestures on the touchscreen yield intuitive contour programming. Since Klartext is the primary format for files and exporting from the Heidenhain control, existing NC programs can continue to be used.

The typical workpiece processed on the Zimmermann machine is P20 steel, which is the industry standard for molds, along with various aluminum materials. The primary types of tool holders are HSK 63 and HSK 80, which are used for cutting and laser touch probing. Additionally, standard carbide cutting tools and inserts are commonly employed.

Currently, the Zimmermann machine at Century operates on two shifts and is often managed remotely, even in low-light or lights-out conditions. “During the very long runs we do on the Zimmermann, maintaining tight tolerances is key, and the machine, plus its onboard control technology, make that happen for us,” Tom Bradford says.

Related Content

Ejector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

Century Tool Invests in Cheto Machine for Deep-Hole Drilling With Milling

Seven-axis CNC strings together gundrill and milling programs, enhancing Century Tool’s moldmaking process.

Read MoreVIDEO: 6 Factors a Mold Builder Should Consider in a CNC Control

Many mold builders choose high-speed cutting over EDM because CNCs are able to meet the required tolerances and finishes. The control is key to this. Here we break down what a mold builder should look for in a CNC control.

Read MoreStability, High Speed, Flexibility of Five-Axis Portal Milling Machine Reduces Rework for Mold Builder

The thermo-symmetrical construction of a five-axis portal milling machine with a center-guided Z-axis enables higher accuracy, reducing rework. Also, the symmetrical design and the guide arrangement increase stability and save weight, making the machine more dynamic, productive and energy-efficient.

Read More