Share

Read Next

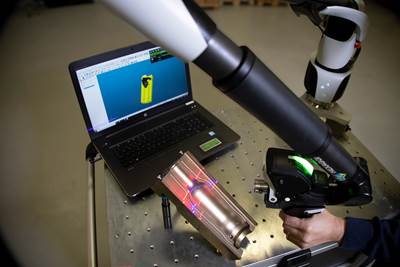

Precision mold being inspected on an all-digital coordinate measuring machine (CMM). Source (all images): Hexagon Manufacturing Intelligence

In moldmaking, precision is crucial and time is money. As demand grows for increasingly complex geometries, tighter tolerances and faster delivery, inspection must evolve from a post-process checkbox to a streamlined, data-rich step within the broader production workflow. Today’s most advanced coordinate measuring machines (CMMs), scanners and software platforms are doing just that — enabling mold shops to inspect smarter, not harder.

By combining high-speed scanning, tactile probing, automation-ready systems and software that simplifies both planning and execution, modern inspection technologies are helping mold shops reduce rework, support quality at every stage and empower a new generation of users to work at the pace of production.

High-Speed Scanning for Complex Geometries

Non-contact laser scanning has emerged as a powerful ally in the mold shop, particularly when dealing with freeform surfaces, reflective finishes or variably textured components. With the right technology, these challenging products are accessible to any machine shop.

At a recent trade show, a shop brought an automotive lighting mold. Its highly polished lens surfaces posed a challenge to most scanning systems, many of which required powdering the part to reduce reflectivity. In contrast, modern scanning systems with adaptive “shine” technology handled the reflective surface directly — no powder, no prep. Parts as tricky as water bottles or chrome-plated inserts can now be scanned on the fly, capturing rich point cloud data with micron-level accuracy.

Why does this matter? Because mold and die components often pass through several machining stages. Using portable metrology tools, operators can verify features in-process, catching issues early, validating toolpaths and skipping redundant rework. Scanning becomes a sanity check that saves hours.

With the recent introduction of laser scanners directly on machine tools, which offer repeatability within microns, inspection is moving even closer to the cutting action. With combined inspection and machining platforms, operators can now scan, compare to CAD and make decisions without moving the part off the machine.

In the most forward-looking moldmaking operations, inspection is no longer an isolated activity. It’s a fully integrated part of a connected digital workflow — anchored by the digital twin.

Tactile Probing for High-Precision Features

Despite the rise of non-contact tools, tactile probing remains a must-have for certain mold features. Deep, narrow channels and fragile inserts still call for the delicacy and control of touch-trigger or analog scanning probes.

In these cases, modern CMM strategies rely on a combination of low-force probing, digital simulation and smart planning. Before a single point is touched, simulation tools validate the probing path against the digital twin of the mold and CMM, minimizing risk and ensuring optimal contact angles. This simulation-led approach helps shops handle fragile or hard-to-reach areas with confidence.

Thanks to multisensor CMM platforms, tactile probing no longer has to exist in isolation. The same inspection program can combine laser scanning and tactile touch, automatically switching between sensors based on the embedded product manufacturing information (PMI) in the CAD model. These transitions happen relatively seamlessly, with little need for manual intervention. Simply plug in the model, and the software extracts the relevant information, allowing the best sensor to be chosen for the task.

Integrating Automation and Sensors

A major leap in productivity comes from automation, not just in machining, but in inspection itself. One key enabler is automated sensor handling. Where calibration and setup for multiple probes once took over an hour, today’s systems can self-calibrate entire sensor arrays in minutes. With only a few button pushes, users can queue up a multisensor inspection that flows from one modality to the next, all while maintaining traceable accuracy.

This is especially useful in mold shops running electrode or EDM tooling, where repeatability is everything. If your inspection routine can’t switch sensors or tools with speed and precision, you risk introducing variation right before the mold hits the press.

Some mold shops now go even further, integrating inspection into fully automated production cells. Palletized electrodes can be loaded into machining centers, inspected inline by CMMs with barcoded part recognition and fed back into the loop with real-time feedback. A centralized software layer coordinates everything — machining programs, inspection routines and quality decisions — ensuring that what goes into the mold is what was intended, without costly rework downstream.

Inspecting As a Connected Workflow

In the most forward-looking moldmaking operations, inspection is no longer an isolated activity. It’s a fully integrated part of a connected digital workflow — anchored by the digital twin.

The digital twin includes not just the CAD model, but the entire ecosystem of the part: its Product Manufacturing Information (PMI), CMM, CNC machine, tooling, fixturing, even the planned inspection strategy. With this foundation, shops can create highly automated workflows that adapt in real-time, prioritizing throughput, avoiding collisions and reallocating machine time dynamically to optimize utilization.

As measurement data flows back to the machining center, shops gain a closed-loop process that supports “shift left” quality control — catching deviations early, before they snowball into costly defects. Companies are already adopting these models, using digital twins to orchestrate inspection and machining across facilities and reduce manual touchpoints.

One of the biggest game-changers in mold inspection is usability.

Empowering with Smarter Software

One of the biggest game-changers in mold inspection is usability. Gone are the days when only seasoned metrology experts could program a CMM. Today’s software platforms offer intuitive interfaces, cloud-based collaboration tools and AI-powered assistants that generate reliable measurement routines from the PMI in a CAD model.

Offline programming and simulation tools mean that CMMs spend more time measuring and less time idle. Operators can prepare inspection plans while machines are busy, using digital simulation to validate results and minimize shop-floor surprises.

These tools don’t just drive productivity; they help mold shops bridge the workforce gap. With an aging expert population and a shortage of skilled metrologists, AI must do the heavy lifting. Solutions like digital, cloud-based hubs and simulation-led workflows are making it possible to train up new talent quickly and keep quality moving at the speed of production.

Bringing Inspection Up to Speed

From reverse engineering to final inspection, today’s moldmakers need tools that match the pace and precision of their craft. By integrating high-speed scanning, tactile probing, automation and smart software, inspection is becoming faster, easier and more connected.

Related Content

How to Quickly Check Cooling Channels

Smart hole inspection validates possible leakages and strangulations in the cooling channels by doing tightness and flow rate tests.

Read More7 Measurement Innovations Transforming Moldmaking

Smart sensors and sophisticated process and measurement data management are driving intelligent moldmaking to new heights.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreHow to Achieve Automated Measurement With Advanced Touch Probes and Laser Systems

A combination of lasers, probes and software help moldmakers automate in-process cutting tool and workpiece measurement.

Read MoreRead Next

Intuitive, Easy-to-Use Inspection Software for Portable Probing and Scanning Simplifies Mold Measurement

Enhanced inspection software and hardware with portable measurement, analysis and reporting improves productivity.

Read MoreAutomatic Inspection System Performs Comprehensive, Real-Time Surface Inspections for 3D-Printed Molds

LaserVision from Aligned Vision, to be on display at IMTS 2022, uses laser feedback for large-scale additive manufacturing to perform inspection without the need to stop production, ensuring continuous, quality manufacturing.

Read More3-D, Non-Contact Scanning for Inspection: Info for Moldmakers

Understanding the differences and similarities between CMM and 3-D scanning allows moldmakers to adapt to, apply and leverage 3-D scanning technology within their shop environment.

Read More