Analysis

Versatile Profilometer Eliminates Blind Spots, Measures Glossy Surfaces

Motorized rotational scanning for performing a wider variety of measurements.

Read MoreWorkflow Automation Transforms Moldmaking Operations

Legacy Precision Molds implements JobTraQ’s no-code workflow automation software to better coordinate complex production tasks across departments, improving efficiency, tracking and decision-making.

Read MoreInjection Mold Design Review Checklist

A mold design review serves as the critical checkpoint before production begins, verifying that the mold satisfies both engineering requirements and manufacturing constraints.

Read MoreBest Practices for Injection Mold Design: The Mold Design Review, Part 4 of 4

Structured mold design reviews are strategic imperatives that resolve design flaws early, minimizing waste and ensuring dimensional accuracy in production.

Read MoreMMT Chats: Ingenuity in Action: Industrial Molds' Engineers Redefine Moldmaking

Industrial Molds’ engineering team showcases ingenuity and precision through complex DFM challenges, delivering optimized tooling, adaptability and customer-driven solutions.

WatchCompact Surface Roughness Tester for Easy, Accurate On-Site Measurement

Advanced technology ensures accurate roughness evaluation, conforming to the latest ISO 21920 standards.

Read MoreHow Industrial Molds Conquered a Complex Impeller Fan Mold Challenge

Expert engineering team overcomes complex impeller fan mold challenges through innovation, precision and collaborative problem-solving.

Read MoreHow to Put AI to Work in EDM

AI streamlines EDM with dashboards, NFC integration, data extraction, wire cutter design, G-code optimization and tool setter enhancements.

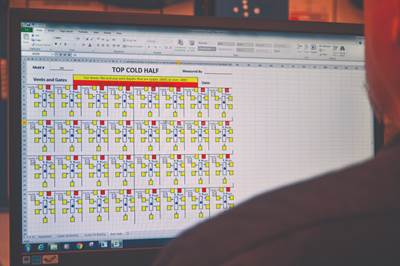

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreAutomating Mold Inspection: Integrating Speed, Precision and Usability Across Complex Workflows

Whether you're verifying an electrode, checking a complex cavity or feeding quality data into a closed-loop workflow, today’s CMM technologies are turning inspection into a competitive advantage, not a bottleneck.

Read More