Advanced Mold Monitoring for Efficiency

ITW Body and Fuel optimizes mold performance through real-time monitoring and integrated asset management, achieving significant reductions in downtime, scrap rates and maintenance costs.

With the rapid advancement of technology, molders and OEMs are under pressure to optimize their operations. This optimization requires understanding the location, performance and maintenance status of molds, as these elements are critical for maintaining the efficiency of molds, which are among the most valuable assets in manufacturing operations.

But how do you gather this intelligence? The answer is global mold monitoring and asset management technology, which is exactly what ITW Body and Fuel and Progressive Components partnered up to do.

The Problems With Manual Maintenance

Traditionally, many in the industry, including ITW, have relied on Excel for tracking mold locations, preventive maintenance (PM) status and incidents such as broken lifters. While Excel serves its purpose, it lacks the sophistication required for comprehensive mold management.

“Issues such as tracking maintenance between shifts, identifying recurring problems and recognizing trends are challenging with manual systems. For example, without a proper tracking system, a recurring issue like a broken lifter on the same tool might go unnoticed, leading to missed opportunities for preventive action,” says Paul DeJong, plant manager for ITW Body and Fuel.

Before investing in a more advanced asset-tracking system, ITW faced several challenges, including unplanned downtime and difficulties tracking tooling. DeJong’s plant operates 48 injection molding machines with around 150 tools, along with an additional 200 service tools stored off-site. Manually tracking these tools often led to confusion and inefficiencies, such as tools being misplaced or unaccounted for.

ProFile provides relevant and role-based data and KPIs at your fingertips. Whether at a workstation in the plant or off-site, critical data is accessible.

Advantages of an Advanced Tracking System

Implementing an advanced tracking system, such as ProFile, has addressed these challenges. DeJong explains that having a system where one can easily look up the location of a mold, whether on-site or off-site, simplifies operations.

The ProFile system provides access to the cloud-based database via tags and plates affixed to the asset — the mold. QR code technology enables GPS tracking and database entries from mobile phones via a subscription service.

“For example, when molds are stored off-site, the system provides real-time updates, ensuring that the correct tools are in the right place at the right time,” DeJong says.

Breaking Down the Benefits

In the automotive sector, where customer-owned tooling is common, keeping molds operational beyond their intended life cycle can lead to hidden costs. DeJong’s team uses the tracking system to set up triggers that alert them when a mold approaches its cycle limit, enabling them to request a new mold or refurbishment from the customer. This proactive approach helps avoid the frustration and inefficiencies of using outdated or worn-out molds.

Real-time data is a crucial component of the ProFile system. By continuously monitoring mold performance, the system enables DeJong’s team to anticipate PM needs and schedule them more effectively.

“For example, if a mold is due for PM within the next week, the system alerts the team, enabling them to prepare and minimize downtime. This level of monitoring extends to work orders as well, helping to track recurring issues, who completed the work and when it was done,” says Sujit Sheth, monitoring business manager for Progressive Components.

“This heightened awareness contributes to a general increase in Overall Equipment Effectiveness (OEE) by 10% to 12% because the team can monitor cycle times, identify when molds are running out of spec and address issues before they escalate.”

DeJong contrasts this with its previous Manufacturing Execution System (MES), which required extensive wiring and manual setup. The old system often failed to capture data when something went wrong with the wiring or setup, leading to gaps in the information.

“In contrast, ProFile tracks data continuously, without the need for manual input or extensive wiring, ensuring that the team always has the information they need to maintain optimal mold performance,” DeJong says.

One of the significant benefits of the ProFile system is its integration capabilities. It can be seamlessly integrated into existing ERP or MES systems, making it adaptable for various industries, particularly injection molding. This adaptability ensures the system works efficiently within ITW’s existing infrastructure while providing the necessary data for effective mold management.

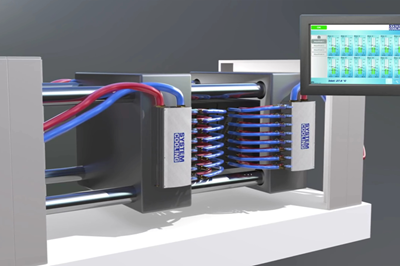

ProFile molding system seamlessly integrates with ERP/MES platforms, enabling efficient mold management and real-time data collection across diverse injection molding operations.

“Often, shops use multiple systems for different tasks, which is fine as long as the data from each system can be integrated into a single point of access. Without this integration, managing the data becomes cumbersome, reducing the overall effectiveness of the system,” Sheth explains.

Work orders are another area where the ProFile system excels. DeJong emphasizes the importance of tracking work orders to identify recurring issues and determine the true cost of maintenance.

“If a knockout pin needs replacing, the system logs the event, including the time, shot count and who performed the work. Over time, this data helps the team identify trends, such as components wearing out faster than expected, enabling them to adjust PM schedules accordingly,” DeJong says.

Another practical feature of the ProFile system is its “file cabinet” function. This feature enables users to store all relevant documents, such as process instructions and PM reports, in one easily accessible location. This eliminates the confusion that often arises when documents are stored on a shared network drive, where they can be misplaced or become outdated. Having a centralized repository for all tool-related information simplifies both the production and maintenance processes.

“If a knockout pin needs replacing, the system logs the event, including the time, shot count and who performed the work. Over time, this data helps the team identify trends, such as components wearing out faster than expected, enabling them to adjust PM schedules accordingly.”

The system’s cellular connectivity further enhances its usability. DeJong explains that ITW Body and Fuel operates five plants across North America, including two in Mexico. The ProFile system’s cellular capability enables it to be deployed quickly and efficiently in any location, without the need for extensive IT infrastructure. This flexibility has proven invaluable, especially in plants where on-site IT support is limited.

Mobile access promotes system utilization throughout the facility as well as off-site. Whether it be operator workstations, tooling repair or maintenance, ProFile offers a complete mobile application.

Cost savings are a significant outcome of implementing the Profile system. DeJong reports cycle time savings of 14%-19% due to streamlined processes, fewer unscheduled mold stoppages, saving over $175K annually and decreased rejects/scrap rates by 15%-20%.

In addition, the system’s ability to track and log scrap in real-time increases awareness among setup and mold technicians, leading to more thoughtful decision-making on the shop floor.

“This heightened awareness contributes to a general increase in OEE by 10% to 12% because the team can monitor cycle times, identify when molds are running out of spec and address issues before they escalate,” DeJong says.

Sheth adds that when selecting a mold monitoring system, it’s essential to ensure it fits the specific application. Not all systems are suitable for every operation and understanding the unique needs and capabilities of the shop is crucial.

ITW Body and Fuel’s experience with the ProFile system demonstrates the value of advanced mold monitoring and asset management. By adopting a system that provides real-time data, integrates with existing infrastructure, and simplifies the tracking of molds and maintenance, the company has achieved significant operational efficiencies and cost savings.

Related Content

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreWhat Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreRead Next

5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

Read MoreVIDEO: Enhancing Data-Driven Decisions with Cloud-Based Mold Monitoring

Steps to improve data-driven decision-making and key features of a cloud-based system for mold monitoring and asset management.

Read MoreVIDEO: Simplify Mold Management of Your Tooling Fleet

In this digital demo, Progressive Components explains its basic asset management and mold monitoring system, ProFile, where it is possible to monitor all your assets in one place.

Read More