5 Ways to Improve Supply Chain Visibility and Efficiency

Mold builders play an important role in creating smart, connected and transparent supply chains.

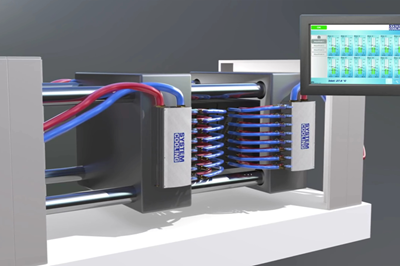

Install smart sensors on tooling and production lines to collect real-time data, facilitating proactive maintenance and efficient capacity management. Source | eMoldino

Supply chain disruptions and inefficiencies can significantly impact operations and profitability. Many manufacturers struggle to meet their targets due to continued supply chain challenges, so a strategic overhaul is clearly needed. The future of manufacturing lies in smart, connected and transparent supply chains.

Are you ready to move your shop into this new era of operational excellence? Here are five steps to enhance supply chain visibility and drive operational excellence:

- Embrace comprehensive digital transformation. Many manufacturers have implemented digital solutions in certain areas, but full technological integration remains elusive. To close information gaps and prevent delivery delays, companies must commit to industry-wide digital adoption. This includes implementing real-time capacity planning tools and advanced analytics platforms across all operations, from molding to final assembly.

Tip: Invest in a holistic digital ecosystem that connects all aspects of your supply chain, enabling seamless data flow and decision-making.

- Implement real-time tooling digitalization. Tooling digitalization is transforming the manufacturing landscape by providing unprecedented visibility into production processes. By integrating sensors and IoT devices, companies can monitor tooling capacity, production output and maintenance needs in real-time.

Tip: Deploy smart sensors across your tooling and production lines to gather real-time data, enabling proactive maintenance and efficient capacity management.

- Leverage AI (Artificial Intelligence) for predictive analytics and decision-making. AI is revolutionizing supply chain management by offering deep insights into production processes and enabling data-driven decision-making. AI-powered systems can predict potential disruptions, optimize production schedules and identify areas for improvement.

Tip: Implement AI-driven tool management systems to enhance operational efficiency, reduce unexpected stoppages, and improve overall production output.

By integrating sensors and IoT devices, companies can monitor tooling capacity, production output, and maintenance needs in real-time.

- Diversify and digitally connect your supplier network. Relying on single-source suppliers can lead to significant risks in times of crisis. To mitigate these risks, companies should diversify their supplier base and create a digitally connected network that provides real-time insights into supplier capacity and performance.

Tip: Build a resilient, diverse supplier network enhanced by digital connectivity to ensure production continuity and mitigate supply chain risks.

- Prioritize supply chain transparency and collaboration. Improving visibility within the supply chain is crucial for enhancing efficiency and reducing costs. By fostering transparency and collaboration with suppliers, companies can conduct thorough root-cause analyses and gain a competitive edge.

Tip: Establish collaborative platforms and data-sharing protocols with suppliers to increase transparency and enable joint problem-solving and optimization efforts.

By implementing these strategies, manufacturers can transform their supply chains from potential liabilities into powerful assets. Real-world examples demonstrate the significant impact of these approaches: one company saved $25.25 million by implementing sensor technology to align supply with demand, while another realized $214,000 in savings through tooling digitalization.

Embracing these digital solutions and AI-driven systems is not just about solving current challenges — it's about positioning your company at the forefront of industry evolution. By prioritizing supply chain visibility and efficiency, you can unlock new growth opportunities, ensure operational resilience, and lead the way in market responsiveness.

Related Content

Achieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.

Read MoreMMT Chats: Helping Small Manufacturers Embrace AI

IT Expert Mina Girges shares simple ways to implement AI by starting small, fostering innovation, integrating securely and scaling strategically to enhance efficiency.

Read MoreMMT Chats: The Rise of Tooling Digitalization

MoldMaking Technology Editorial Director Christina Fuges chats with Bob Vancoillie with the Consumer Division of Johnson & Johnson about OEM corporate initiatives for digitizing tooling.

Read MoreWhat Is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read More